Chicken House Design Of Using A Type Layer Battery Cage

This Chicken House Design Of Using A Type Layer Battery Cage is meticulously tailored to maximize productivity and welfare in chicken farming operations.

Chicken farming has undergone a transformative evolution in recent years, with a pronounced shift toward technology-driven efficiency. In this detailed exploration, we unravel the intricacies of a comprehensive design solution that revolves around the integration of A-type layer battery cage. This Chicken House Design Of Using A Type Layer Battery Cage is meticulously tailored to maximize productivity and welfare in chicken farming operations.

The Evolution of Efficiency in Poultry Farming

Modern poultry farming demands a sophisticated approach to design, and the introduction sets the stage by highlighting the evolving landscape of efficiency. We delve into the factors driving the adoption of advanced equipment, emphasizing the pivotal role of A-type layer battery cages in this paradigm shift.

A-Type Layer Battery Cage System

we delve deeply into the A-type layer battery cage system, dissecting essential parameters and highlighting its distinctive advantages:

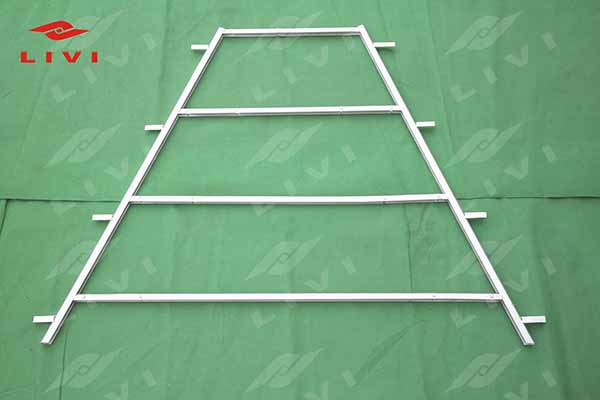

Cage Structure Analysis: Elevating Bird Comfort and Longevity

- Comfort-Oriented Design: An exploration of features crafted to enhance the well-being of the birds, ensuring they have ample space to move, perch, and exhibit natural behaviors.

- Easy Management Features: Insights into design nuances that simplify daily management tasks, making it convenient for poultry farmers to monitor, handle, and care for the layers.

- Durability Emphasis: Highlighting the significance of durable materials and construction methods, contributing to the overall structural integrity and extending the lifespan of the equipment.

Material Quality Matters: Enhancing Durability and Longevity

- Durable Construction: Exploring the types of materials employed in the construction of the cages, showcasing their resilience to wear, tear, and environmental factors.

- Corrosion Resistance: Noting the importance of materials that are resistant to corrosion, especially in settings where exposure to moisture is a factor.

- Longevity Benefits: Discussing how the quality of materials directly contributes to the extended lifespan of the equipment, providing a cost-effective and sustainable solution for poultry farmers.

Optimizing Space Utilization: Maximizing Welfare and Productivity

- Space Efficiency Strategies: Exploring design elements that maximize the utilization of space within the cages, ensuring that each bird has adequate room for movement and natural behaviors.

- Welfare-Driven Design: Emphasizing the correlation between optimal space allocation and the mental and physical well-being of the layers, ultimately enhancing their productivity.

- Strategic Layout Planning: Discussing how thoughtful cage placement and arrangement contribute to efficient space utilization within the larger poultry house.

Efficient Feeding and Egg Collection: Streamlining Operations

- Automated Feeding Systems: Exploring the advantages of automated feeding mechanisms, reducing labor requirements, minimizing feed wastage, and ensuring a consistent and controlled feeding regimen.

- Innovative Egg Collection Solutions: Highlighting design features that simplify the egg collection process, promoting cleanliness, reducing breakage, and enhancing overall egg quality.

- Labor Reduction and Resource Optimization: Discussing how the integration of these systems contributes to streamlined daily operations, reducing labor costs, and optimizing resource utilization for improved farm profitability.

Chicken House Design Examples: Tailoring Solutions for Varied Capacities

LIVI Machinery case studies exemplify the adaptability and scalability of the chicken house design solution:

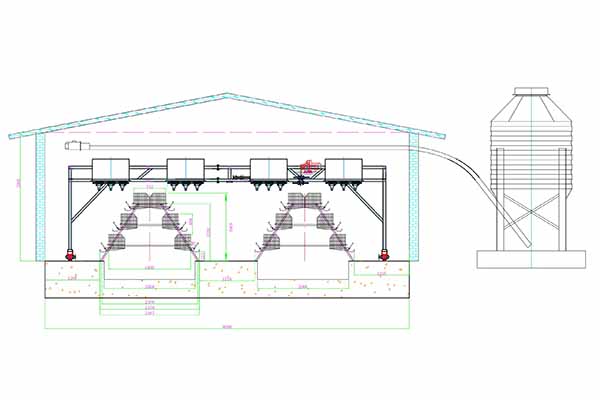

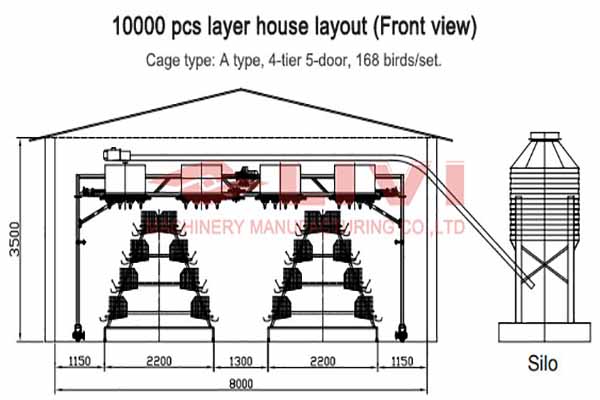

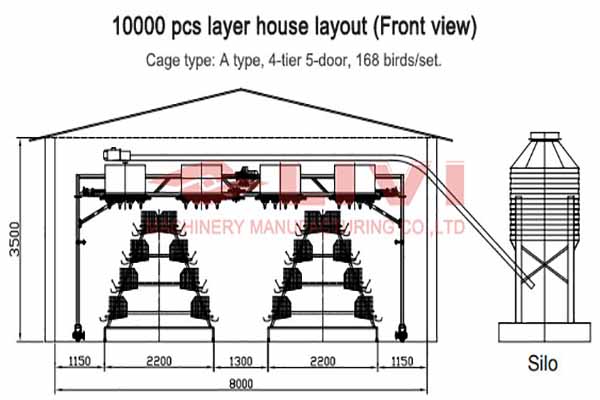

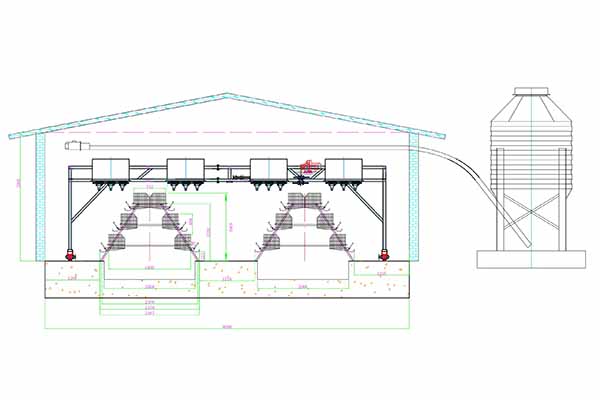

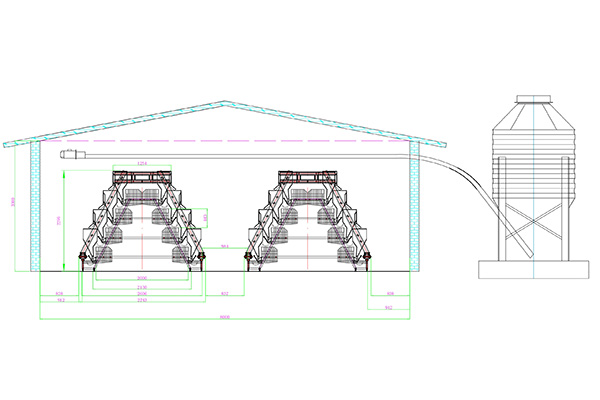

10,000 Layers Chicken House Design:

Chicken house Address: Nigeria

Chicken house area: 65*8*3.5M

Number of chickens raised: 10,000 laying hens

A type layer batery cage specifications: 1950*450*480mm, 4 layers

Required layer cage: 60 sets of A-type layer cage

Chicken cage in the chicken house: two rows, each row 30 sets of poultry battery cage

5000 Layers Chicken House Design:

Chicken house Address: Zambia

Chicken house area: 60*8*3.7M

Number of chickens raised: 5000 chickens

A type layer batery cage specifications: 1950*350*380mm, 3 layers

Required layer cage: 54 sets of A-type layer cage

Chicken cage in the chicken house: two rows, each row 27 sets of poultry battery cage

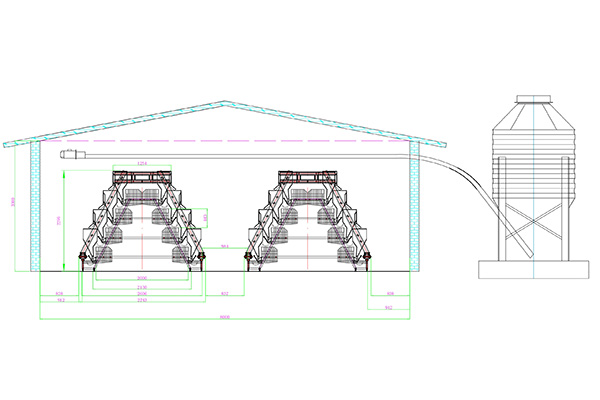

15000 Layers Chicken House Design:

Chicken house Address: Ghana

Chicken house area: 100*9*3.5M

Number of chickens raised: 15000 chickens

A type layer batery cage specifications: 1950*450*410mm, 4 layers

Required layer cage: 94 sets of A-type layer cage

Chicken cage in the chicken house: two rows, each row 47 sets of chicken battery cage

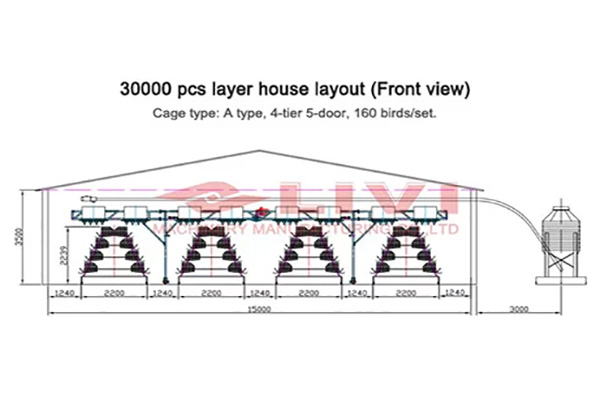

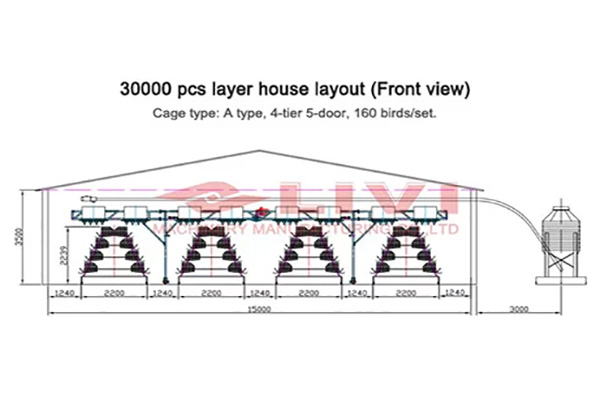

30000 Layers Chicken House Design:

Chicken house Address: Tanzania

Chicken house area: 100*9*3.5M

Number of chickens raised: 30000 chickens

A type layer batery cage specifications: 1950*450*410mm, 4 layers

Required layer cage: 188 sets of A-type layer cage

Chicken cage in the chicken house: 4 rows, each row 47 sets of poultry battery cage

Livi Machinery’s Free Chicken House Design Service: Collaboration for Success

Overview of Livi’s Commitment: An exploration of how Livi Machinery goes beyond equipment provision by offering a collaborative service focused on designing success.

Collaborative Approach: Insights into the interactive process between Livi Machinery and farmers. It demonstrate how designs are tailored based on specific needs, preferences, and regional considerations.

Professional Insights: The inclusion of professional insights, recommendations, and adjustments. It showcase how Livi Machinery brings expertise to the table for optimal design outcomes.

Conclusion

A-type layer battery cages emerge not just as a pragmatic choice but as a transformative force, revolutionizing the landscape of poultry farming. Through a nuanced understanding of design parameters and a collaborative approach with Livi Machinery. Poultry farmers can embark on a journey towards unparalleled efficiency and success in their chicken raising endeavors.

Join the Poultry Farming Revolution!

Ready to elevate your poultry farming game? Dive into the efficiency and scalability offered by A-type layer battery cages. Let’s sculpt a bespoke chicken house design tailored to your needs!

Leave us a message with your breeding numbers and chicken house area!