Automatic Manure Removal Equipment

Feces cleaning equipment type: flat belt type feces cleaning equipment; Scraper cleaning equipment

Function: Clean up chicken manure, improve the efficiency of raising chickens, and keep the chicken house clean and hygienic.

Product Introduction

Maintaining a clean and sanitary environment is essential for the health and productivity of poultry. Automatic Manure Removal Equipment emerges as a crucial tool in poultry farming to streamline the removal of waste.

Automatic Manure Removal Equipment is designed to efficiently and hygienically remove poultry waste from the farming environment. By automating the process, it reduces labor requirements and ensures a more consistent and effective waste management system.

Product Classification

Automatic Manure Removal Equipment comes in two main classifications, each serving specific purposes:

- Scraping-Type Manure Removal Equipment: This type employs scraping mechanisms to collect and remove manure from the poultry house. The scraping action gathers waste into a designated collection area for subsequent disposal.

- Belt-Type Manure Removal Equipment: Belt-type systems use conveyor belts to transport manure out of the poultry house. The conveyor system ensures a continuous and automated removal process, enhancing overall efficiency.

Scraping-Type Manure Removal Equipment

Scraper-Type Manure Removal Equipment is a fundamental component of modern poultry farming, offering an efficient and automated solution for waste management. Its operational principles ensure systematic waste removal, and the advantages it brings in terms of labor efficiency, hygiene, and cost savings make it an indispensable tool for poultry farmers aiming for a productive and sustainable farming operation.

Scraper cleaning equipment is usually used in combination with A type A cage.

It is usually necessary to dig out a manure ditch under the cage.

The width of the ditch is generally 2.2M and 2.4M.

According to the choice of cage, dig different widths of manure ditch.

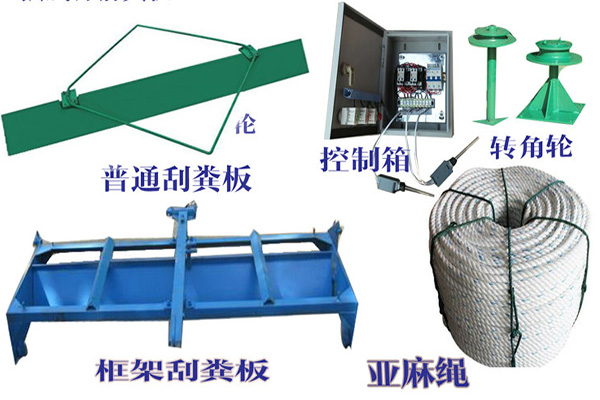

Scraper cleaning equipment accessories: motor, steering wheel, scraper, flax rope

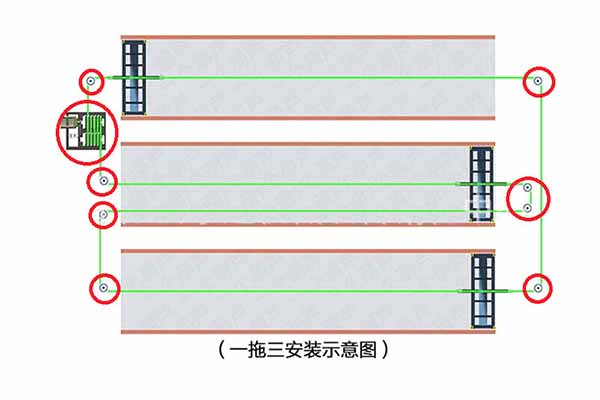

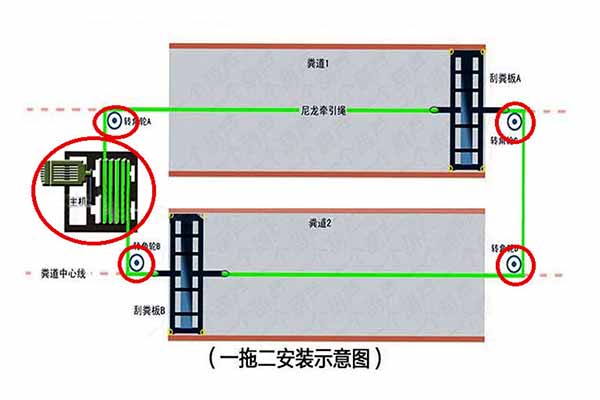

The two most commonly used types of scraper cleaning equipment are one to tow and one to three. As the name suggests, it’s a motor with steering wheels and a scraper that can clean two or three rows of ditches.

Installation and operation of scraper cleaning equipment

Belt-Type Manure Removal Equipment

Flat belt manure cleaning equipment is generally used with H-type chicken cages.

Flat belt manure removal equipment is installed under each layer of cage to catch chicken manure. The strip on the flat belt cleaning equipment carries the chicken manure to the designated location.

Generally, the flat belt manure cleaner is connected to the septic tank outside the chicken house.

Product Operation

The operation of Automatic Manure Removal Equipment involves systematic processes to ensure the effective removal of waste:

Scraping-Type Operation:

- Scrapers, either mechanical or hydraulic, move along the floor of the poultry house.

- Manure is pushed towards a central collection point or conveyor system.

- The collected waste is then transported out of the house for disposal.

Belt-Type Operation:

- Conveyor belts run continuously, transporting manure from the poultry house to an external collection area.

- The belts are equipped with mechanisms to ensure the even distribution and removal of waste.

- The waste is efficiently deposited into designated containers for disposal.

Product Advantages

Automatic Manure Removal Equipment offers several advantages for poultry farmers:

- Labor Efficiency: The automation of manure removal reduces the need for manual labor, saving time and resources.

- Hygiene and Disease Control: Prompt and efficient waste removal minimizes the risk of disease transmission, ensuring a healthier flock.

- Consistent Cleaning: Automatic systems provide consistent and thorough waste removal, contributing to a cleaner and more comfortable environment for the poultry.

- Time and Cost Savings: The automation of waste removal processes leads to significant time and cost savings for poultry farmers.

- Enhanced Productivity: A cleaner and more hygienic environment positively impact poultry health and, subsequently, productivity.

Conclusion

Automatic Manure Removal Equipment plays a vital role in modern poultry farming by providing an efficient and automated solution for waste management. With the classification into scraping-type and belt-type systems, the versatility of these tools caters to different farm layouts and preferences. The operational processes of scraping or belt conveyance ensure the systematic removal of waste, and the advantages of labor efficiency, hygiene, and cost savings make Automatic Manure Removal Equipment an indispensable asset for poultry farmers aiming for a productive and sustainable operation.