Broiler Ground Raising System

Specification: Customized according to customer’s breeding scale or chicken house size (Length*Width).

Raw Material: PP Plastic

Lifespan: 15-20 Years

Product Introduction

In the ever-evolving landscape of poultry farming, a transformative approach known as the Broiler Ground Raising System is reshaping the industry. This comprehensive guide delves into the intricacies of this innovative system, exploring its product introduction, detailed features, ground-raising equipment, design considerations, advantages, and a comparative analysis with cage-based broiler raising.

The Broiler Ground Raising System is designed to revolutionize broiler farming by providing a conducive environment for broilers to thrive. Unlike traditional cage systems, this approach prioritizes open ground space, allowing broilers to exhibit natural behaviors such as walking, stretching, and foraging. The system aims to enhance the overall well-being and health of broilers during their growth cycle.

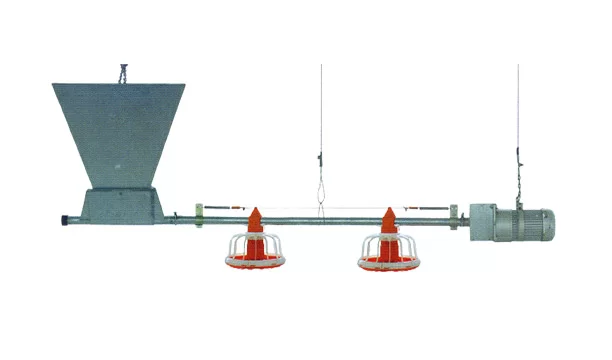

| Equipment Parts | Automatic Broiler Pan Feeding System |

| Feed Silo | Material: hot dip galvanized Sheet thickness: 1.00mm Capacity: recommended feed amount for 2-3 days. |

| Main Feeding Line | The capability of conveying food: 1400KG/h Material: High-carbon manganese steel Sensor imported from Germany |

| Pan Feeding Line | Hot galvanized pipe contains the auger, which can transfer the feed from the vice feed hopper to the end of the house. Broiler automatic feeder pan capacity: 30-35 broilers/per feed pan |

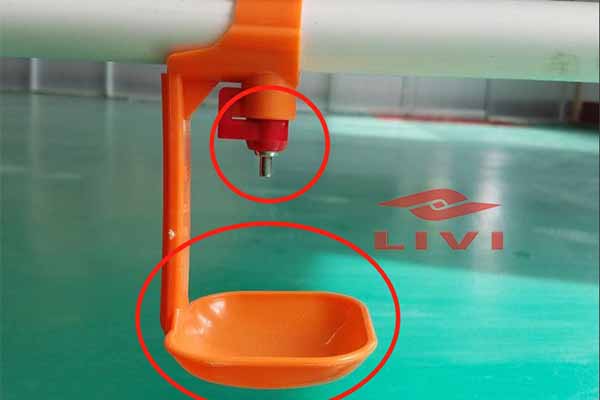

| Drinking Line | Water pipe with drinking nipples. Nipple capacity: 8-10 broilers/per nipple. |

Product Details and Ground Raising Equipment

A. Open Space Design

The design of the Broiler Ground Raising System emphasizes spaciousness, granting broilers the freedom of movement. This section provides an in-depth explanation of the layout and considerations for optimal density to ensure a stress-free environment for the broilers.

B. Feeding and Watering Systems

Efficient feeding and watering systems are critical for supporting broiler nutrition. This segment explores the features of automated systems that contribute to convenience and precision in maintaining the health of the broilers.

C. Shelter and Climate Control

The shelter design is crucial for protecting broilers against weather elements. This section discusses the elements of a well-designed shelter and the implementation of climate control measures to maintain optimal conditions for the broilers.

The water connection is sealed to prevent contamination.

The drinking nipple is highly sensitive and rotates 360 degrees.

Flexiable to adjust and a long lifespan

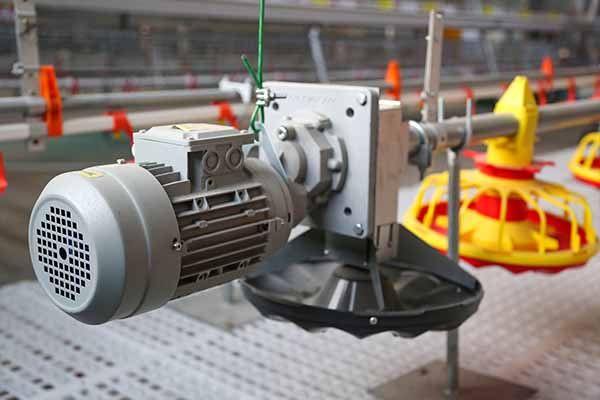

Voltage: 380V 50hz 3 phases

Rated power: 0.75-1.1KW

Taiwan brand

Capacity: 90-120KG

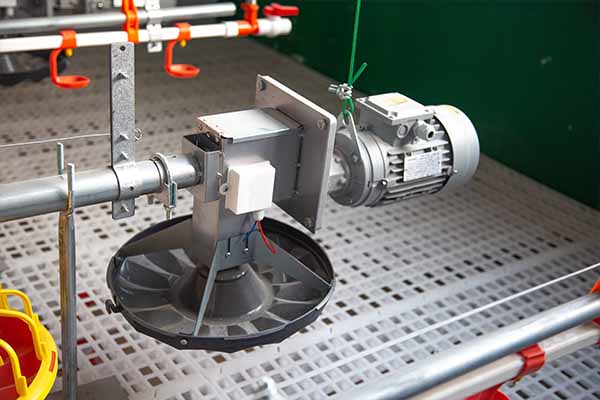

Material: Hot dip galvanized sheet Thickness: 1.00mm

Imported from German

Capacity: 30-35 broilers / per broiler feeder pan.

Ground Raising Design

A. Layout Considerations

A well-planned layout is essential for the efficiency of ground-raising operations. This part of the guide explores considerations for waste management and hygiene, ensuring a clean and organized environment.

B. Biosecurity Measures

To prevent disease outbreaks, biosecurity measures are imperative. This section delves into the incorporation of preventive measures in the ground-raising design to ensure the health and safety of the broilers.

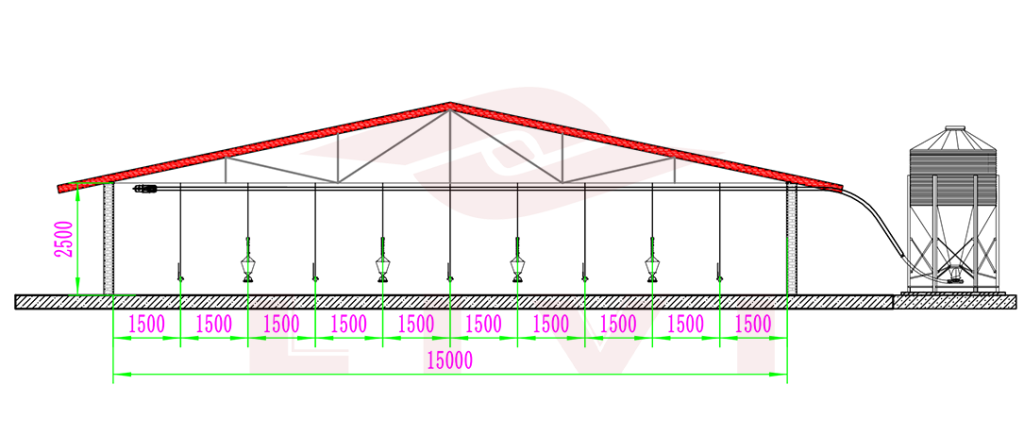

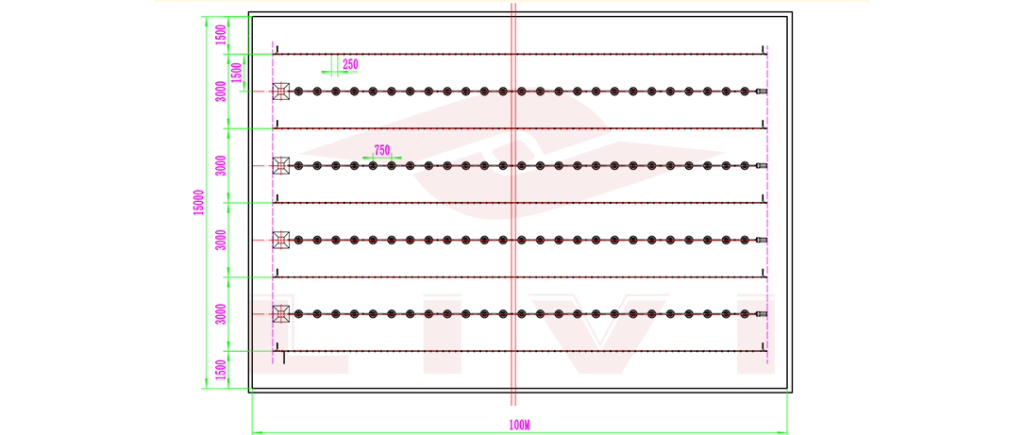

Layout Explanation: (Unit: mm)

1. Chicken Shed Size: 100000mm x 15000mm x 2500mm.

2. Configuration: 4 feed lines, 5 water lines.

3. Rearing Capacity: 15 birds/m².

The water line and the material line are staggered.

Generally, the water line and the material line are separated by 1.5M

The water trays are 25 cm apart

The trays are 75 cm apart

There is usually one more water line than the material line

Design the waterline layout according to the width of the chicken house.

Advantages of Broiler Ground Raising

A. Improved Broiler Welfare

Open space promotes natural behavior, leading to enhanced physical and mental well-being for the broilers. This segment discusses the positive impact of the ground-raising system on the overall welfare of the broilers.

B. Healthier Growth and Development

Reduced stress and improved air quality contribute to healthier growth and development in broilers. This part explores the influence of these factors on broiler weight gain and overall health.

C. Quality of Meat

Ground-raised broilers are known to yield better meat quality. This section provides insights into how natural exercise influences muscle development and, consequently, the quality of meat produced.

Ground Raising vs. Cage Raising

The choice between ground raising and cage raising involves a careful consideration of various factors. Ground raising promotes natural behaviors, healthier growth, and superior meat quality. It aligns with changing consumer preferences for ethically produced poultry. Cage raising offers efficiency in space utilization but raises concerns about animal welfare. As the industry shifts towards more sustainable and ethical practices, the comparative analysis leans towards ground raising as a forward-looking and humane approach to poultry farming.

Livi Machinery’s Service

- High quality Chicken cage

- Complete chicken raising equipment

- 365-Day First-Class Service

- Get a Free Quote – Design Within 24 Hours

- 15-45 Days Production

- 60-Day Installation

- Customizable service

- Free chicken house design

Conclusion

The Broiler Ground Raising System represents a paradigm shift in broiler farming, prioritizing animal welfare, efficiency, and quality outcomes. As the industry evolves, understanding the intricacies of ground raising becomes crucial for farmers looking to enhance efficiency, profitability, and meet consumer expectations. Embrace the future of broiler farming with the Broiler Ground Raising System, where ethical practices and efficient production converge for a sustainable and thriving industry.