160,000 Bird Poultry System: An In-depth Analysis for Kenyan Broiler Farms

Understanding the 160,000 Bird Poultry System in Kenya

The Kenyan poultry industry has been witnessing significant growth over the years. One of the key factors contributing to this growth is the adoption of modern, efficient poultry farming systems. This article provides an in-depth analysis of the 160,000 bird poultry system, focusing on its implementation and benefits in the Kenyan market.

Key Features of the 160,000 Bird Poultry System

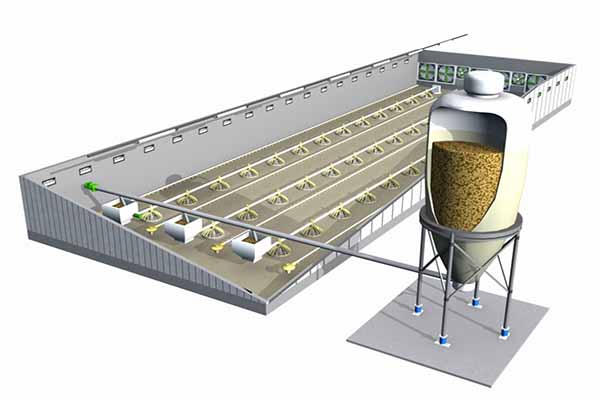

– Design: The system is designed to accommodate up to 160,000 birds, making it suitable for large-scale operations.

– Automated Feeders and Waterers: To ensure optimal health and growth, automated feeders and waterers are integrated into the system.

– Environmental Control: Advanced climate control mechanisms maintain optimal temperatures and humidity levels, reducing stress on birds.

– Sanitation: Regular cleaning protocols are implemented to prevent diseases and maintain biosecurity.

Benefits of Implementing a 160,000 Bird Poultry System

– Increased Productivity: The system can achieve an impressive average production of around 80-100 million eggs annually.

– Cost-Effectiveness: With reduced labor requirements and increased production, the cost per bird decreases significantly.

– Sustainability: The system is energy-efficient and environmentally friendly, reducing the carbon footprint of poultry farms.

Implementation Considerations

– Space: Ensure that the farm has adequate space for the system to function effectively.

– Capital Investment: The initial investment for a 160,000 bird poultry system is significant. However, it can offer a high return on investment in the long run.

– Training: Farm staff need to be trained to operate and maintain the system efficiently.

Market Analysis

According to recent data, Kenya’s poultry industry is expected to grow at a CAGR of 4.8% from 2018 to 2023. This growth can be attributed to factors such as rising per capita meat consumption and an increasing demand for egg production.

Table: Comparative Analysis of Traditional and 160,000 Bird Poultry Systems

| Aspect | Traditional System | 160,000 Bird System |

|———————–|———————————-|——————————-|

| Space Requirement | 10-20 square meters per bird | 1-2 square meters per bird |

| Feed Consumption | 3.5-4 kg per bird per day | 2-3 kg per bird per day |

| Water Consumption | 1.5-2 liters per bird per day | 1-1.5 liters per bird per day |

| Egg Production | 240-300 eggs per bird per year | 320-400 eggs per bird per year |

| Energy Efficiency | Lower | Higher |

Conclusion

Investing in a 160,000 bird poultry system can be a game-changer for Kenyan broiler farms. With the right implementation and management, such systems offer significant advantages in terms of productivity, cost-effectiveness, and sustainability.

For those interested in exploring the feasibility of implementing a 160,000 bird poultry system on their farm, feel free to leave a comment or contact us directly for a free poultry farm design and equipment quote.