Battery Cage System for Layers: The Ultimate Investment for Egg Production Efficiency

Understanding the Battery Cage System

The battery cage system is a popular method in the layer chicken industry for egg production. This system ensures optimal conditions for laying hens, contributing to higher egg yield and better hen welfare. The cost-effectiveness of the battery cage system has made it a preferred choice for many poultry farms.

A well-designed battery cage system can significantly enhance the efficiency of egg production. Here are some key aspects to consider:

- Space allocation per hen: A standard battery cage measures approximately 0.2 to 0.25 square meters, ensuring comfortable space for each bird.

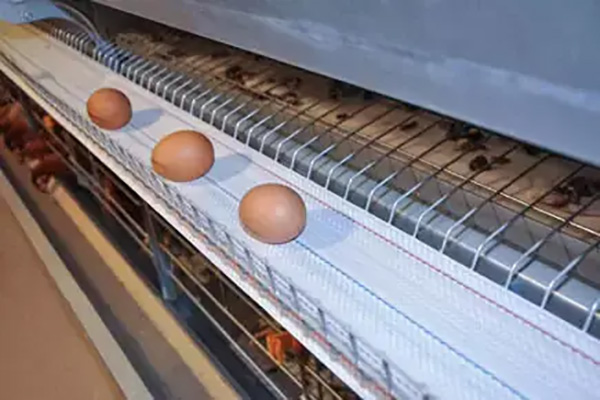

- Egg collection systems: Automated systems help in efficient egg collection, reducing labor costs and minimizing breakage.

- Airflow and lighting: Proper ventilation and lighting are crucial for hen health and productivity.

Battery Cage System for Layers: Pricing Factors

The price of a battery cage system for layers varies depending on several factors. Below are some key pricing considerations:

| Factor | Description | Average Price Range |

|---|---|---|

| Cage Size | The size of the battery cage system directly impacts the number of hens it can accommodate and thus the cost. | $100 – $150 per cage |

| Quality of Material | High-quality materials ensure durability and safety, but also increase the cost. | $20 – $30 additional per cage |

| Automated Features | Additional features like automatic feeders and waterers can increase the initial cost but save on labor in the long run. | $50 – $200 additional per feature |

The average cost for a complete battery cage system for layers, including installation, ranges from $10,000 to $30,000 per thousand hens.

Why Invest in a Battery Cage System for Layers?

Investing in a battery cage system for layers can provide several benefits for your poultry farm:

- Increased Egg Yield: Properly managed battery cages can lead to a higher egg yield per hen, improving your overall productivity.

- Reduced Labor Costs: Automated systems and efficient design can minimize the need for manual labor.

- Better Hen Welfare: A well-designed battery cage system provides a comfortable and hygienic environment for laying hens.

- Profitability: With higher egg yields and reduced costs, the battery cage system can lead to increased profitability for your farm.</li

>

>

According to recent studies, farms using a battery cage system can expect an egg yield of up to 320 eggs per hen per year.

Conclusion

A battery cage system for layers is a sound investment for any poultry farm aiming to improve egg production efficiency and overall profitability. While the initial cost may be significant, the long-term benefits and cost savings make it a worthwhile investment.

For more information on battery cage systems for layers, including p rices and custom designs, please feel free to contact us. We offer free chicken farming design solutions and equipment quotations from Livi Mechanical.

rices and custom designs, please feel free to contact us. We offer free chicken farming design solutions and equipment quotations from Livi Mechanical.