Optimizing Chicken Farming in Uganda with Galvanized Layer Cages for 100,000 Hens

As the demand for poultry products continues to rise in Uganda, efficient and reliable farming solutions are essential for success. One such solution is the use of galvanized layer cages designed to accommodate up to 100,000 hens. This article explores the benefits of these cages and how they can enhance the productivity of chicken farming operations.

Galvanized Layer Cages: A Robust Solution for Large-Scale Chicken Farming

Galvanized layer cages are constructed with high-quality steel, coated with a zinc-rich layer for corrosion resistance. This ensures the longevity of the cages, making them a cost-effective investment for large-scale chicken farming operations.

- Increased Capacity: These cages can house up to 100,000 hens, allowing for high-density farming without compromising on space or ventilation.

- Improved Health: The structured design of the cages helps prevent the spread of diseases, as hens are less likely to come into contact with their feces and other waste products.

- Easy Maintenance: Galvanized steel is easy to clean and sanitize, reducing the risk of disease outbreaks and ensuring a healthy environment for the hens.

- Longevity: With proper maintenance, galvanized layer cages can last up to 20 years, providing a long-term investment for your farm.

According to a study by the Uganda Poultry Association, farms that have implemented galvanized layer cages have seen a 30% increase in egg production and a 25% reduction in disease-related mortality.

Design Considerations for 100,000  Hen Chicken Farms

Hen Chicken Farms

When setting up a large-scale chicken farm with 100,000 hens, several factors need to be considered to ensure optimal performance:

- Space Allocation: Each hen requires approximately 0.5 square meters of space. Plan your layout accordingly to ensure there is enough room for the hens to move around comfortably.

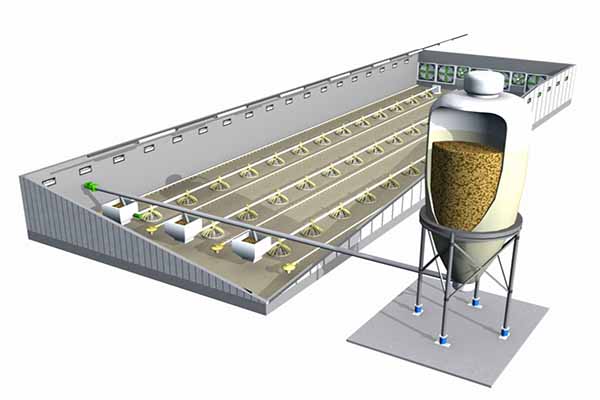

- Airflow and Ventilation: Proper ventilation is crucial to maintain a healthy environment. Ensure that your farm has adequate air exchange to prevent the buildup of ammonia and other harmful gases.

- Water and Feed Supply: A reliable water and feed supply system is essential. Consider the use of automated feeders and waterers to minimize labor costs and ensure consistent access to resources.

- Monitoring and Management: Regular monitoring of the hens’ health and productivity is key. Invest in a robust monitoring system to track the performance of your flock and make informed decisions.

For a detailed analysis of your farm’s specific needs, consider consulting with a professional agricultural consultant or a company specializing in poultry farming equipment.

Get Your Free Chicken Farm Design and Equipment Quote from LIVI Mechanical

At LIVI Mechanical, we understand the unique challenges of large-scale chicken farming in Uganda. Our team of experts can provide you with a free, customized chicken farm design and equipment quote tailored to your specific requirements. Contact us today to get started on your journey to success in the poultry industry.