Battery Broiler Chicken Cages for 180,000 Birds in Uganda: The Ultimate Guide

Understanding the Needs of a Large Scale Broiler Chicken Farm

Uganda’s poultry industry is rapidly growing, and with the demand for broiler chicken increasing, it is crucial for investors and farmers to stay ahead of the curve. A battery broiler chicken cage system designed for 180,000 birds can be a significant investment. This article will guide you through the essential aspects of implementing such a system.

Why Battery Cages are Ideal for Large Scale Broiler Chicken Production

Battery cages offer numerous advantages for large-scale broiler chicken production, especially for a farm with 180,000 birds:

– High Efficiency: Battery cages allow for the housing of a large number of birds in a compact space, maximizing land use.

– Sanitation: The structured design of battery cages aids in easy cleaning and reduces the risk of disease outbreaks.

– Consistent Growth: Cages provide a controlled environment that supports consistent growth and uniformity among the birds.

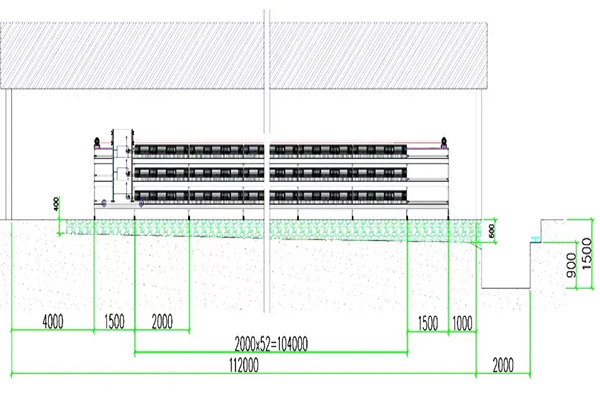

Key Features of a Battery Broiler Chicken Cage for 180,000 Birds

When considering a battery broiler chicken cage system for your 180,000 birds in Uganda, here are some key features to look for:

– Space per Bird: Ensure that each bird has enough space to move around comfortably, typically around 0.7 square feet per bird.

– Ventilation: Proper ventilation is essential for the health and well-being of the birds, especially in a high-density setting.

– Material Quality: High-quality steel or durable plastic materials ensure the longevity and structural integrity of the cages.

Cost and Return on Investment

The initial cost of setting up a battery broiler chicken cage system for 180,000 birds can be substantial. However, the following factors can help in understanding the return on investment:

– Lower Feed Conversion Ratio: Efficiently managed battery cage systems can result in a lower feed conversion ratio, leading to cost savings.

– Reduced Labor Costs: Automation features in modern cage systems can reduce labor requirements.

– Higher Egg Production: Healthier birds in a controlled environment tend to produce more eggs, improving profitability.

Implementation and Maintenance

Implementing a battery broiler chicken cage system requires careful planning and attention to detail:

– Professional Installation: Hire a reputable installation team to ensure the system is set up correctly.

– Regular Maintenance: Schedule regular maintenance checks to prevent downtime and costly repairs.

Conclusion

Investing in a battery broiler chicken cage system for 180,000 birds in Uganda can be a game-changer for your poultry business. By understanding the key aspects of the system and the factors influencing its success, you can make an informed decision.

For a free, customized design and equipment quote, leave a comment below or contact us at LIVI Mechanical. Our team of experts is ready to assist you in taking your poultry farm to the next level.