Optimizing Broiler Cage Equipment for a 150,000 Chicken Farm in Togo

Understanding the Broiler Cage Equipment Needs for a Large Scale Chicken Farm in Togo

In the fast-growing poultry industry of Togo, the establishment of a 150,000 chicken farm necessitates efficient broiler cage equipment. With the right setup, you can maximize production and ensure the well-being of your birds. This article provides an overview of the essential equipment required and the benefits they offer.

Essential Broiler Cage Equipment for a 150,000 Chicken Farm

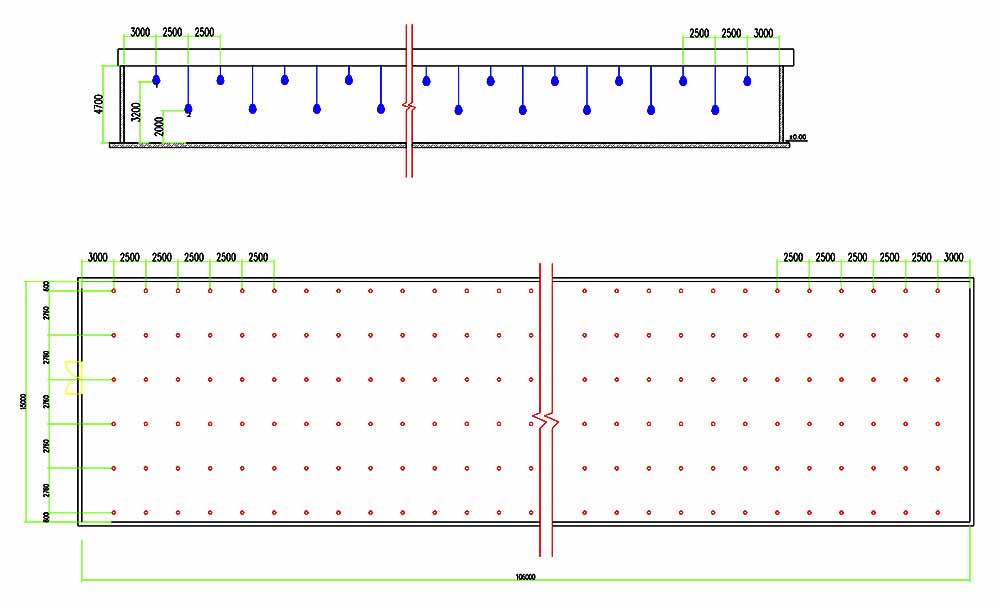

– Cage Systems: The core of a broiler farm, these cages are designed to hold chickens in a compact space. They come in various sizes, with the capacity to hold up to 40 chickens each. The size and quantity of the cages will depend on the farm layout and the available space.

– Ventilation Systems: Proper ventilation is crucial for maintaining air quality and reducing the risk of disease. Ventilation systems should ensure a consistent flow of fresh air while preventing drafts and excessive temperatures.

– Heating and Cooling Equipment: The broiler farm needs to provide controlled temperatures for the chickens. During colder months, heating systems such as fans or radiant heaters may be required. In warmer months, efficient cooling systems will help maintain the optimal temperature for growth.

– Feeding Systems: Automated feeding systems ensure that the chickens receive a consistent diet. The systems can be set to dispense the correct amount of feed at predetermined intervals.

– Watering Systems: Access to clean, fresh water is vital for chicken health. Gravity-fed watering systems or automatic waterers are ideal for large farms.

– Lighting Systems: Proper lighting can significantly impact chicken growth and productivity. A consistent light cycle can help synchronize the chickens’ natural rhythms.

– Manure Removal Systems: Regularly removing manure is essential for maintaining hygiene and preventing disease. Automated systems can help streamline this process.

Benefits of Efficient Broiler Cage Equipment

– Increased Productivity: With the right equipment, a 150,000 chicken farm can achieve higher production rates and better overall performance.

– Reduced Costs: Efficient equipment can lead to lower operating costs, as less energy and resources are required.

– Improved Chicken Welfare: Properly designed cages and equipment contribute to the overall well-being of the chickens, reducing stress and disease.

– Better Farm Management: Automated systems allow for better monitoring and management of the farm, leading to more informed decision-making.

Projected Costs and Return on Investment

According to recent studies, setting up a 150,000 chicken broiler farm in Togo can cost around $1.2 million. However, with efficient equipment and proper management, the return on investment can be significant. On average, a well-run broiler farm can generate revenue of $1.8 million per year.

| Equipment | Estimated Cost |

|---|---|

| Cage Systems | $400,000 |

| Ventilation Systems | $100,000 |

| Heating and Cooling Equipment | $150,000 |

| Feeding Systems | $100,000 |

| Watering Systems | $50,000 |

| Lighting Systems | $50,000 |

| Manure Removal Systems | $60,000 |

| Total | $1,250,000 |