Optimizing Chicken Battery Cage Systems for 120,000 Chickens in Kenya

Kenya’s poultry industry is rapidly growing, with an increasing demand for high-quality chicken products. One of the key components to efficient poultry farming is the chicken battery cage system. This article will explore the design and implementation of a battery cage system capable of housing up to 120,000 chickens, focusing on efficiency, comfort, and cost-effectiveness.

Understanding the Battery Cage System

A battery cage system is a method of housing chickens where each bird is kept in a separate cage. This system is popular due to its ease of management and ability to produce consistent egg quality. For a farm housing 120,000 chickens, the following considerations are crucial:

- Cage Size: The size of the battery cage should be sufficient to allow chickens to stand, turn around, and lie down comfortably. On average, a battery cage for a layer chicken should be about 0.25 square meters.

- Space Utilization: Efficient space utilization is vital to maximize output. For 120,000 chickens, a total area of approximately 30,000 square meters would be required.

- Airflow and Ventilation: Proper airflow and ventilation are essential to maintain a healthy environment for the chickens, reducing the risk of respiratory diseases.

- Manure Management: A reliable manure management system is necessary to keep the farm clean and hygienic, minimizing the risk of disease outbreaks.

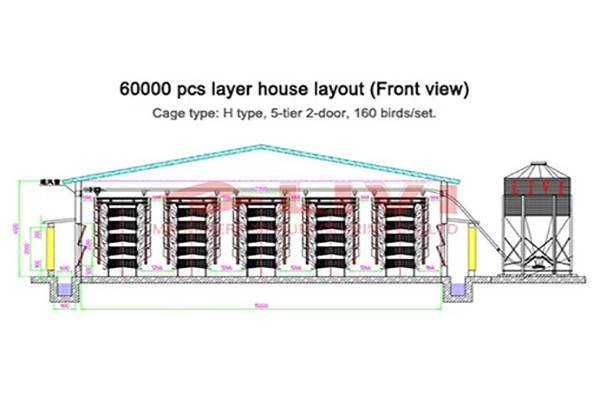

Designing the System for 120,000 Chickens

When designing a battery cage system for 120,000 chickens, the following steps should be considered:

- Site Selection: Choose a location with good drainage, access to water, and electricity supply.

- Building Construction: Construct the farm with a steel frame structure, which is durable and resistant to weather conditions.

- Cage Installation: Install the battery cages on raised platforms to facilitate cleaning and reduce the risk of disease transmission.

- Feeding and Watering Systems: Implement automated feeding and watering systems to ensure the chickens receive proper nutrition and hydration.

- Environmental Control: Install environmental control systems, such as fans and heaters, to maintain optimal conditions for the chickens.

According to data from the Kenya Poultry Industry Association, an efficient battery cage system can produce an average of 280 eggs per hen per year. For a farm housing 120,000 chickens, this would result in approximately 33.6 million eggs per year.

Conclusion

Designing and implementing an efficient b attery cage system for 120,000 chickens in Kenya requires careful planning and attention to detail. By focusing on cage size, space utilization, airflow, manure management, and environmental control, a farm can maximize its output and ensure the health and well-being of its chickens.

attery cage system for 120,000 chickens in Kenya requires careful planning and attention to detail. By focusing on cage size, space utilization, airflow, manure management, and environmental control, a farm can maximize its output and ensure the health and well-being of its chickens.

Are you interested in optimizing your chicken battery cage system? Contact us today for a free design consultation and equipment quote from Livi Mechanical. Our team of experts is ready to help you achieve success in the poultry industry.