Optimizing poultry farming with an Automatic 80,000 Chicken Cage System in Nigeria

Introduction

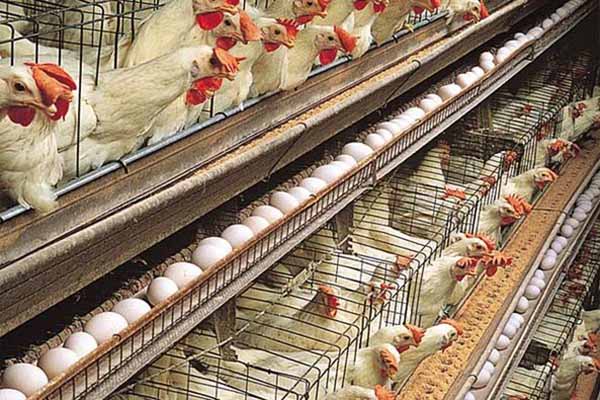

The poultry industry in Nigeria is experiencing rapid growth, with a significant increase in the demand for chicken. To cater to this growing market, an efficient and scalable solution is needed. An automatic poultry cage system for 80,000 chickens can be a game-changer for Nigerian farmers and investors alike. In this article, we’ll explore the benefits and features of such a system, providing insights for both established farms and new ventures.

Benefits of an Automatic Poultry Cage System

- Increased Production Efficiency: An automatic system can significantly improve the productivity of a poultry farm. By automating feeding, watering, and ventilation, farmers can save time and reduce labor costs.

- Healthier Birds: With automated monitoring and controlled environments, the risk of diseases can be minimized, leading to healthier chickens and higher quality produce.

- Space Optimization: The system’s design ensures that each chicken has adequate space, promoting a comfortable living environment.

Key Features of the 80,000 Chicken Cage System

| Feature | Description |

|---|---|

| Automated Feeding | Feeder systems ensure consistent and precise feeding, optimizing growth rates. |

| Watering System | Continuous access to clean water helps maintain chicken health. |

| Climate Control | Automated ventilation and temperature regulation create an ideal environment for chicken welfare. |

| Monitoring and Data Collection | Real-time monitoring systems track the health and performance of the flock. |

Implementation and Cost Considerations

Implementing an automatic poultry cage system for 80,000 chickens requires careful planning and investment. The initial setup costs can be substantial, but the long-term benefits often outweigh the initial investment. Factors to consider include:

- Land Availability: Sufficient space is needed for the system and chickens.

- Energy Supply: Reliable electricity is essential for running the automated systems.

- Water Supply: Access to a clean water source is crucial for the chickens’ hydration.

- Skilled Labor: Operators must be trained to manage the automated systems effectively.

Conclusion

Investing in an automatic poultry cage system for 80,000 chickens in Nigeria can revolutionize the poultry farming industry. With the right setup and management, farms can achieve higher productivity, better chicken health, and increased profitability. If you’re considering such an investment, contact Livi Mechanical for a free poultry farm design plan and equipment quotation. Our team of experts is ready to help you get started.

Are you interested in transforming your poultry farm with an automatic system? Leave a comment below or contact us directly to get started today!

<img src="http://www.qualitychickenfarm.com/wp-content/uploads/2025/05/different-of-a-type-3-tiers-chicken-cage-and-4-tiers-cage-11.jpg ” alt=”inserted image”>

” alt=”inserted image”>