Automatic Layer Cage Equipment for 80,000 Chickens in Uganda: The Ultimate Solution for Efficient Poultry Farming

In the ever-evolving poultry industry, the demand for efficient and automated solutions is on the rise. With the rapid growth of the chicken farming sector in Uganda, a robust automatic layer cage equipment is essential for successful and sustainable operations. This article will delve into the importance of such equipment, its benefits, and how it can significantly improve the productivity of a 80,000 chicken farm.

The Need for Automatic Layer Cage Equipment

Farming 80,000 chickens requires a considerable amount of space, labor, and resources. Traditional farming methods are often inefficient and may lead to increased disease risks and reduced productivity. An automatic layer cage system provides a more streamlined approach to poultry farming, offering several benefits that can make a significant impact on the overall success of the farm.

- Reduced Labor Costs: Automatic systems minimize the need for manual labor, saving time and resources.

- Improved Hygiene: The system reduces the risk of disease spread, ensuring healthier chickens.

- Increased Productivity: Automation allows for better management of the flock, resulting in higher egg production.

- Cost-Effective: Long-term savings from reduced labor and improved productivity can outweigh the initial investment.

Key Features of Automatic Layer Cage Equipment for 80,000 Chickens

When choosing automatic layer cage equipment for an 80,000 chicken farm in Uganda, consider the following features to ensure optimal performance and efficiency:

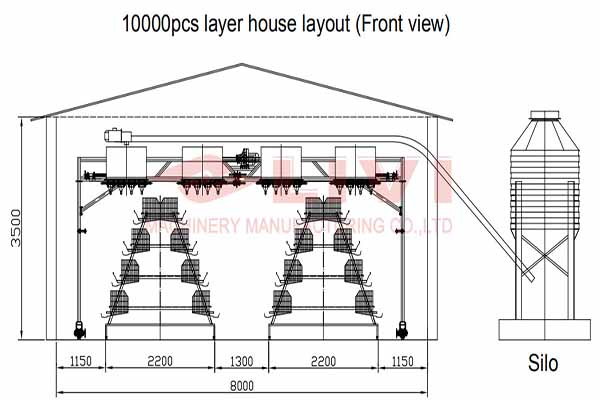

- Capacity: Ensure the system can accommodate 80,000 chickens comfortably, with proper spacing for each bird.

- Automated Feeding: An automated feeding system ensures a consistent supply of feed to the chickens.

- Watering System: A reliable and efficient watering system is crucial for maintaining hydration levels in the flock.

- Airflow and Ventilation: Proper airflow and ventilation help in maintaining a healthy environment for the chickens.

- Manure Removal System: An automated manure removal system reduces labor costs and improves hygiene.

Case Study: A Successful 80,000 Chicken Farm in Uganda

One of our clients, Uganda’s largest poultry farming operations, successfully implemented our automatic layer cage equipment. The farm has seen a 30% increase in egg production and a 20% reduction in labor costs. The improved hygiene and overall efficiency of the farm have made it a leader in the Ugandan poultry industry.

Why Choose LIVI Mechanical?

LIVI Mechanical is a leading provider of automatic layer cage equipment for poultry farms in Uganda. With years of experience and a commitment to quality, we offer tailored solutions to meet the unique needs of each farm. Our team of experts will work closely with you to ensure your farm’s success.

Here’s what sets us apart:

- Customized Solutions: We offer equipment designed specifically for your farm’s requirements.

- Quality Products: Our equipment is built to last, ensuring long-term performance.

- Competitive Pricing: We offer affordable solutions without compromising on quality.

- Excellent C

ustomer Service: Our team is always ready to assist you with any queries or concerns.

ustomer Service: Our team is always ready to assist you with any queries or concerns.

Don’t miss out on the opportunity to transform your poultry farm. Contact us today for a free, no-obligation consultation and receive our exclusive养鸡设计方案 and equipment quotation.