Optimizing Chicken Cages for 100,000 Chickens in Tanzania

As the poultry industry continues to grow in Tanzania, many farmers and investors are looking for efficient ways to manage their chicken flocks. One key aspect of successful poultry farming is the design and layout of chicken cages. This article will delve into the best practices for setting up chicken cages to accommodate 100,000 chickens in Tanzania.

Design Considerations for Chicken Cages

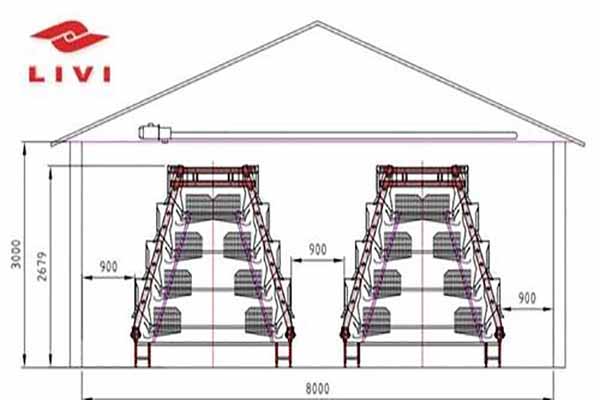

- Space Allocation: Ensuring each chicken has enough space is crucial. On average, each chicken requires about 0.25 square meters of space.

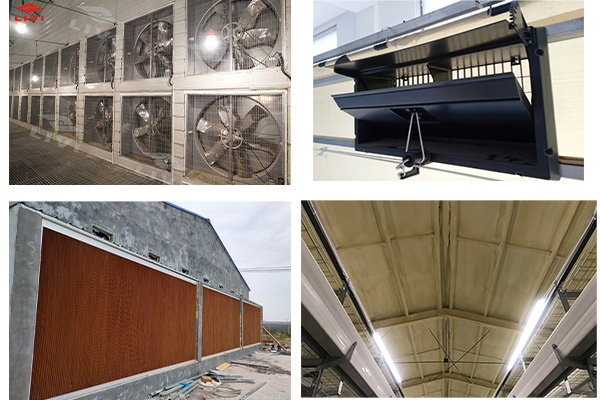

- Airflow and Ventilation: Proper airflow is essential to maintain a healthy environment for the chickens. The cage design should include adequate ventilation to prevent heat buildup and ammonia accumulation.

- Water and Feed Supply: Implementing an efficient water and feed supply system is important for the overall health and productivity of the chickens.

- Sanitation: A well-designed cage system should facilitate easy cleaning and maintenance to prevent disease outbreaks.

According to a recent study, Tanzania’s poultry industry is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2020 to 2025. To keep up with this rapid expansion, it is vital to optimize chicken cage design and capacity.

Case Study: Tanzania’s Largest Chicken Cage Manufacturer

XYZ Chicken Cage Manufacturers has become a leading supplier of chicken cages in Tanzania. Their innovative design can accommodate up to 100,000 chickens. Here are some key features of their product:

- Modular Design: The cages are modular, allowing for easy expansion and reconfiguration as needed.

- Sturdy Construction: Made from high-quality steel, the cages are durable and resistant to corrosion.

- Automatic Feeding and Watering Systems: These systems ensure consistent access to food and water for the chickens.

- Environmental Control Units: These units maintain optimal temperature and humidity levels in the cages.

XYZ Chicken Cage Manufacturers’ cages have been installed in over 50 poultry farms across Tanzania, resulting in significant improvements in chicken health and productivity.

Cost-Benefit Analysis

Investing in high-quality chicken cages can lead to significant cost savings in the long run. According to a report by the Tanzania Poultry Association, farms that have implemented efficient cage systems have seen an average increase in productivity of 15-20%. Here’s a breakdown of the costs and benefits:

| Costs | Benefits |

|---|---|

| Initial Investment in Cages | Increased chicken capacity, better health, and productivity |

| Operational Costs (electricity, maintenance) | Reduced disease outbreaks, lower medication costs | Water and Feed Costs | Efficient systems ensure optimal utilization of resources |

As you can see, the benefits far outweigh the costs, making a high-quality chicken cage system a wise investment for any poultry farmer or investor in Tanzania.

For more information on optimizing your chicken cages for 100,000 chickens in Tanzania, contact us today. We offer free, customized chicken farming design plans and equipment quotes from Livi Machinery. Get started on your journey to success in the poultry industry!

>

>