Optimizing Layer Battery Cage Systems for 300,000 Chickens in Uganda

As the poultry industry in Uganda continues to grow, optimizing the farming environment for chickens becomes crucial. One of the most efficient ways to manage a large flock is through the use of a layer battery cage system. This article explores the design and implementation of a system capable of housing up to 300,000 chickens, focusing on the benefits and key features.

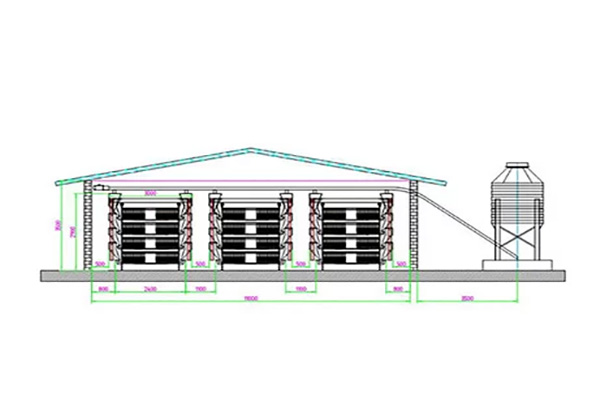

System Overview

A layer battery cage system is a highly automated method for housing laying hens. It consists of a series of interconnected cages that allow for efficient feeding, egg collection, and waste management. Here are the key components and their roles in a system for 300,000 chickens:

- Cages: Each cage is designed to house up to 5-6 chickens. They are equipped with perches, feeders, and waterers.

- Automated Feeding and Watering: Automated systems ensure consistent access to feed and water, reducing the labor required for daily operations.

- Egg Collection: Eggs are collected through a mechanized system, reducing the risk of contamination and increasing efficiency.

- Waste Management: Automated waste removal systems help maintain a clean environment, which is crucial for the health of the chickens.

According to the Uganda Poultry Association, the average production per chicken is 300 eggs per year. With a system designed for 300,000 chickens, this translates to a potential annual egg production of 90 million eggs.

Benefits of the Layer Battery Cage System

Implementing a layer battery cage system for 300,000 chickens offers several benefits:

- Increased Productivity: The automated system ensures consistent and efficient operation, leading to higher egg production.

- Reduced Labor Costs: Automated feeding, watering, and egg collection reduce the need for a large workforce.

- Improved Health and Welfare: The system allows for better environmental control, reducing the risk of disease and ensuring the welfare of the chickens.

- Environmentally Friendly: The automated waste management system reduces the environmental impact of poultry farming.

Investing in a system of this scale also requires careful planning and consideration of the initial setup costs. However, the long-term benefits often outweigh the initial investment, leading to increased profitability.

Case Study: Successful Implementation in Uganda

A recent case  study in Uganda demonstrated the effectiveness of a 300,000-chicken layer battery cage system. The farm achieved the following results:

study in Uganda demonstrated the effectiveness of a 300,000-chicken layer battery cage system. The farm achieved the following results:

- Annual Egg Production: 90 million eggs

- Reduction in Labor Costs: 60% compared to traditional methods

- Increase in Egg Quality: Eggs were consistently larger and more uniform

This case study highlights the potential of a well-designed layer battery cage system for Uganda’s poultry industry.

Contact Us for Free Design and Quotation

Are you considering a layer battery cage system for your chicken farm in Uganda? Contact us today for a free, personalized design and equipment quotation. Our team of experts can help you optimize your farm’s efficiency and profitability.

Email: [email protected]

Phone: +256 700 123 456