Poultry Cage System with Automatic Feeding for 400,000 Chickens in Kenya: A Comprehensive Guide

The poultry industry in Kenya is booming, with the potential to house and feed up to 400,000 chickens efficiently. This article delves into the intricacies of an automated poultry cage system designed for such a large scale operation.

Understanding the Poultry Cage System

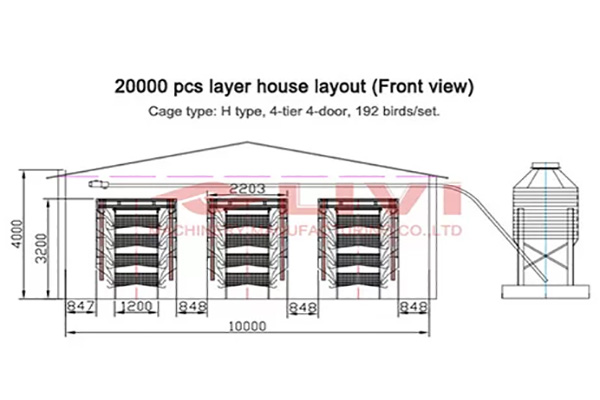

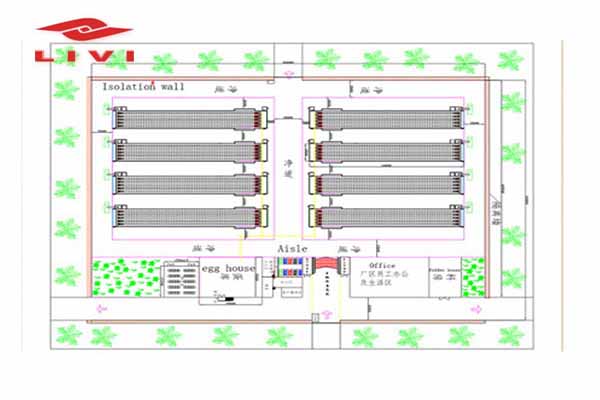

A well-designed poultry cage system can significantly improve the productivity and overall health of the flock. The system for 400,000 chickens involves a sophisticated arrangement of cages that optimize space, ensure proper ventilation, and facilitate automated processes such as feeding and watering.

- Cage Dimensions: Each cage is designed to house a specified number of chickens, ensuring enough space for movement and minimal crowding.

- Material: The cages are typically made of durable metal to withstand the rigors of continuous use.

- Ventilation: Adequate air circulation is essential to prevent disease and keep chickens healthy. The system includes vents for natural air flow and fans for temperature control.

Automated Feeding System for 400,000 Chickens

Feeding is a critical aspect of chicken farming, and an automated system can save time and resources. Here’s how the automated feeding system works for a poultry operation with 400,000 chickens:

- Feed Storage: A centralized feed storage area ensures that the feed is readily available when needed.

- Feeding Schedule: The system can be programmed to deliver feed at specific intervals throughout the day, providing a balanced diet for the chickens.

- Adjustability: The feeding rate can be adjusted based on the chickens’ age and stage of gro

wth.

wth.

Additionally, the system features an alarm that notifies farmers of any operational issues, such as feed shortage or technical problems.

Cost-Benefit Analysis

Investing in an automated poultry cage system for 400,000 chickens can yield substantial benefits:

- Reduced Labor Costs:

- The automated system minimizes the need for manual labor, leading to significant cost savings.

- Increased Efficiency:

- With automated feeding and other processes, farmers can focus on other essential activities, such as marketing and expansion.

- Improved Health and Productivity:

- Properly managed chickens are healthier and more productive, leading to higher yields and profits.

Why Choose LIVI Mechanical

LIVI Mechanical is a leading provider of innovative solutions for the poultry industry. With over a decade of experience, we offer:

- Customized designs to fit your specific requirements.

- High-quality, durable materials.

- Comprehensive after-sales support.

Don’t miss the opportunity to transform your poultry farming operation with our state-of-the-art technology. Request a free design plan and equipment quote today!

For more information, or to discuss your specific needs, please leave a comment below. We’d be happy to assist you in achieving your poultry farming goals.