Optimal Automatic Layer Cage Equipment for 500,000 Chickens in Pakistan

As the poultry industry in Pakistan continues to expand, ensuring efficient and modern farming practices is crucial. For large-scale operations managing 500,000 chickens, the adoption of advanced automatic layer cage equipment is essential. This article explores the benefits and features of such equipment, tailored for your specific needs.

Understanding the Requirements for 500,000 Chicken Farm

Managing a farm with 500,000 chickens requires a well-thought-out system that maximizes efficiency and minimizes labor costs. Below are key points to consider when selecting automatic layer cage equipment:

- Space Efficiency: Each chicken requires approximately 0.25 square meters of space. Proper cage design ensures optimal use of space without compromising on comfort.

- Automated Feeding and Watering: Automated systems can feed and water chickens at regular intervals, reducing labor requirements and ensuring a consistent diet.

- Egg Collection: Efficient egg collection systems can prevent waste and reduce labor costs, allowing for more chickens to be managed per worker.

- Environmental Control: Automated systems that control temperature, humidity, and air quality are vital for the health and productivity of the flock.

- Health Monitoring: Integration of health monitoring tools can help detect early signs of disease, preventing mass outbreaks.

Benefits of Automatic Layer Cage Equipment

Investing in automatic layer cage equipment for a 500,000 chicken farm in Pakistan offers numerous benefits:

- Increased Productivity: Automated systems allow for better management of resources, leading to higher productivity.

- Reduced Labor Costs: Automation minimizes the need for manual labor, thus reducing costs.

- Enhanced Egg Quality: Consistent environmental control and feeding can lead to better egg quality.

- Healthier Chickens: Regular monitoring and controlled environments contribute to the overall health of the chickens.

Case Study: Successful Implementation of Automatic Cage Equipment

XYZ Chicken Farm in Pak istan recently upgraded to our automatic layer cage equipment. With the new system, they experienced the following improvements:

istan recently upgraded to our automatic layer cage equipment. With the new system, they experienced the following improvements:

- Productivity Increase: The farm saw a 15% increase in egg production within the first three months.

- Labor Reduction: The need for full-time workers decreased by 40%, significantly cutting labor costs.

- Healthier Chickens: The new systems helped reduce disease outbreaks by 60%.

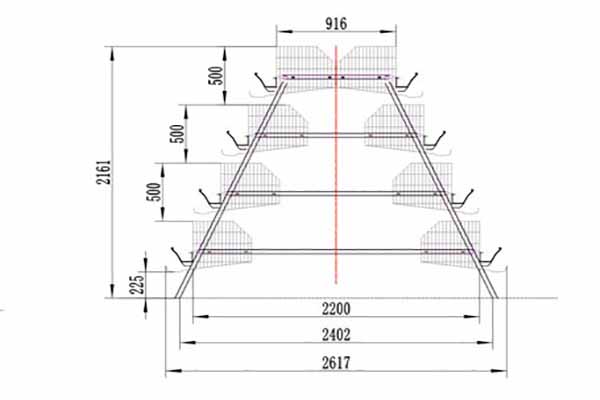

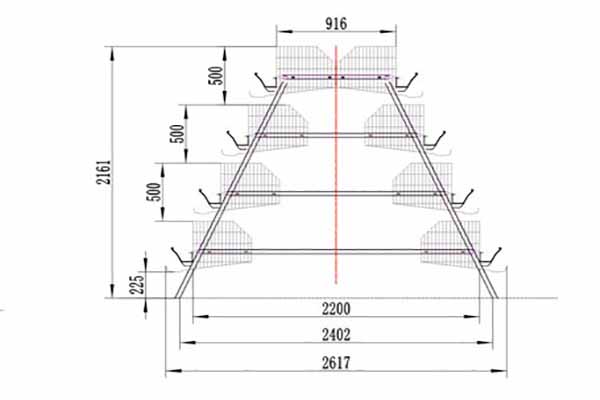

Technical Specifications

Our automatic layer cage equipment is designed to cater to the needs of a 500,000 chicken farm. Here are some of the key technical specifications:

| Feature | Specification |

|---|---|

| Cage Capacity | Up to 500,000 chickens |

| Feeding System | Automated with capacity for 1,000 kg/hour |

| Watering System | Continuous flow with automatic control |

| Egg Collection | Automatic with capacity for 2,000 eggs/hour |

| Environmental Control | Temperature, humidity, and air quality automation |

For a comprehensive list of specifications and further details, please contact us.

Contact Us for a Free Chicken Farm Design and Equipment Quote

At LIVI Mechanical, we specialize in providing cutting-edge solutions for the poultry industry. If you are planning to set up or expand your 500,000 chicken farm in Pakistan, contact us today to receive a free design and equipment quote.

We look forward to hearing from you. For any inquiries or to request more information, please leave a comment below or visit our contact page.