Optimizing Chicken Cage Equipment for 440,000 Chickens in Uganda

With the rapidly growing poultry industry in Uganda, optimizing chicken cage equipment is crucial for sustainable and efficient farming. This article delves into the requirements and solutions for managing a massive 440,000 chicken operation. Below, we outline key considerations, benefits, and the importance of using advanced equipment to enhance productivity.

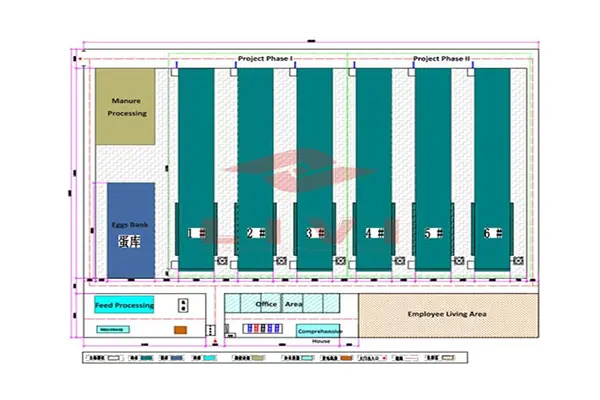

Key Requirements for Chicken Cage Equipment in Uganda

- High-Capacity Chicken Cages

- Automated Feeding Systems

- Effective Waste Management

- Climate Control

- Health Monitoring Tools

For a 440,000 chicken operation, it’s essential to have chicken cages that can accommodate such a large number of birds. High-capacity cages must be designed to ensure comfort and prevent overcrowding.

Benefits of Advanced Chicken Cage Equipment

- Increased Productivity

- Improved Health and Well-being of Chickens

- Reduced Labor Costs

- Enhanced Biosecurity Measures

By using advanced chicken cage equipment, farmers can achieve higher productivity, which is vital for large-scale operations like those in Uganda. Automated systems not only save time but also ensure that each chicken receives adequate nutrition and care.

Climate Control: A Critical Factor

The climate in Uganda varies significantly, and maintaining optimal conditions is crucial for the health of the chickens. Modern chicken cage equipment includes climate control systems that can regulate temperature, humidity, and air quality to keep the birds comfortable year-round.

Waste Management Solutions

Handling waste effectively is essential in a large-scale chicken operation. Advanced waste management systems ensure that manure is collected and disposed of in an environmentally friendly manner, reducing the risk of disease and odor issues.

Health Monitoring: Keeping Chickens Healthy

Regular health monitoring is vital for preventing disease ou tbreaks. Modern chicken cage equipment includes integrated health monitoring tools that provide real-time data on the flock’s health, enabling timely interventions.

tbreaks. Modern chicken cage equipment includes integrated health monitoring tools that provide real-time data on the flock’s health, enabling timely interventions.

Table: Equipment Specifications for a 440,000 Chicken Operation

| Equipment | Quantity | Key Features |

|---|---|---|

| Chicken Cages | 4,400 | High-density, with adjustable settings for different stages of growth |

| Automated Feeding Systems | 4 | Capacity for 10 tons of feed per day |

| Climate Control Units | 8 | Adjustable temperature and humidity control |

| Waste Management Systems | 1 | Automatic manure collection and disposal system |

Health Monitoring  Tools Tools |

1 set | Real-time flock health data monitoring |

For more detailed information on chicken cage equipment for a 440,000 chicken operation in Uganda, or to request a free design and equipment quote from Livi Mechanical, please feel free to leave a comment or contact us directly.