Optimizing Chicken Battery Cage Systems for 120,000 Chickens in Kenya

Understanding the Scale of Chicken Farming in Kenya

The poultry industry in Kenya is rapidly growing, with an increasing demand for chicken meat and eggs. As a result, large-scale chicken farming operations, such as those with 120,000 chickens, are becoming more common. To ensure efficient and humane farming practices, investing in a reliable chicken battery cage system is crucial.

Key Components of a Chicken Battery Cage System

A chicken battery cage system for 120,000 chickens requires careful planning and execution. Here are some essential components to consider:

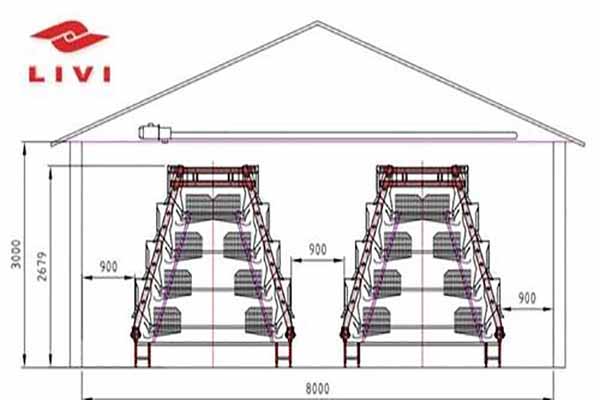

- Cage Design: The design should accommodate the number of chickens and provide adequate space for movement and growth. Each cage should be approximately 0.5 square meters in size.

- Ventilation: Proper ventilation is vital to maintain air quality and reduce the risk of disease. The system should include fans and filters to ensure a healthy environment.

- Feeding and Watering: Automated feeding and watering systems should be integrated to minimize labor costs and ensure consistent nutrition.

- Environmental Control: Temperature and humidity control systems are necessary to create a comfortable living environment for the chickens.

- Health Monitoring: Regular health checks and monitoring tools should be in place to detect and prevent diseases early.

Benefits of Implementing a Large-Scale Battery Cage System

– Increased Efficiency: Automated systems reduce labor costs and improve overall farm productivity.

– Healthier Chickens: Proper ventilation and environmental control reduce the risk of disease and improve the overall health of the chickens.

– Consistent Egg Production: A controlled environment ensures consistent egg production, even during extreme weather conditions.

– Cost-Effective: Although the initial investment may be high, the long-term benefits of increased efficiency and healthier chickens can lead to cost savings.

Case Study: 120,000 Chicken Battery Cage System in Kenya

A successful implementation of a 120,000 chicken battery cage system in Kenya resulted in the following outcomes:

- Increased Production: The farm saw a 15% increase in egg production within the first year.

- Reduced Disease Incidence: The health monitoring system identified and treated early signs of disease, reducing overall mortality rates by 10%.

- Cost Savings: The automated systems reduced labor costs by 30% and improved energy efficiency by 20%.

Conclusion

Investing in a well-designed chicken battery cage system for 120,000 chickens in Kenya can significantly improve your farm’s efficiency, health, and profitability. By integrating the right components and implementing best practices, you can create a sustainable and successful poultry farming operation.

For a free, tailored chicken farming design and equipment quotation, please feel free to leave a comment or contact us directly. Our experts at LIVI Mechanical are here to assist you every step of the way.