Automatic Layer Cage Equipment for 140,000 Chickens in Togo: A Comprehensive Guide

Chicken farming is a vital industry in Togo, and with the increasing demand for poultry products, efficient equipment is essential. This article explores the benefits of automatic layer cage equipment for a 140,000 chicken farm in Togo.

Why Automatic Layer Cage Equipment is Crucial

- Improved Animal Welfare

- Enhanced Productivity

- Reduced Labor Costs

- Increased Profitability

With an automated system, chickens can be managed more effectively, ensuring their well-being and productivity. The use of advanced technology not only minimizes human labor but also reduces the risk of diseases and accidents.

Key Features of Automatic Layer Cage Equipment

- Robust Construction: The equipment is designed to withstand harsh conditions and heavy loads.

- Easy to Install and Maintain: The system is user-friendly and can be easily integrated into existing farms.

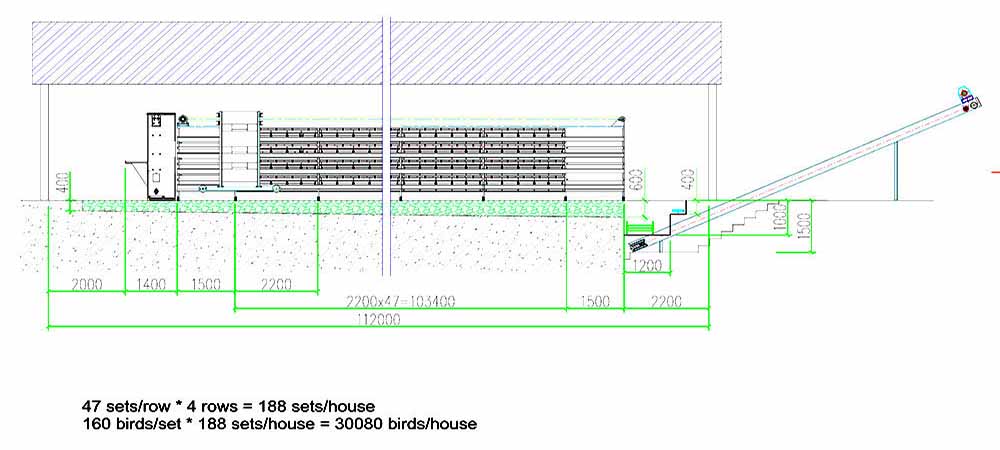

- High Capacity: The equipment is capable of housing up to 140,000 chickens, making it suitable for large-scale farms.

- Customizable Design: The system can be tailored to meet specific farm requirements.

Benefits of Investing in Automatic Layer Cage Equipment

| Benefits | Statistics |

|---|---|

| Increased Egg Production | Up to 20% higher egg production compared to traditional systems |

| Reduced Feed Consumption | Up to 15% lower feed consumption due to optimized feeding systems |

| Lower Mortality Rate | Up to 10% lower mortality rate due to better disease management |

Investing in automatic layer cage equipment for your 140,000 chicken farm in Togo can lead to significant improvements in your farm’s performance and profitability.

Conclusion

Automatic layer cage equipment is a game-changer for the poultry industry in Togo. By enhancing animal welfare, productivity, and profitability, these systems are a must-hav e for large-scale chicken farms. If you’re considering investing in such equipment, contact us today for a free poultry farm design and equipment quote.

e for large-scale chicken farms. If you’re considering investing in such equipment, contact us today for a free poultry farm design and equipment quote.