Automated Egg Collection System for Layers: Revolutionizing the Poultry Industry

The poultry industry has always sought to optimize productivity and reduce labor costs. One significant solution to this challenge is the automated egg collection system for layers. This article explores the benefits and implementation of such a system, providing valuable insights for poultry farm owners and investors.

Why an Automated Egg Collection System is a Game-Changer

- Increased Productivity: An automated egg collection system can process thousands of eggs per hour, significantly boosting the overall productivity of a poultry farm.

- Reduced Labor Costs: Manual egg collection requires a large workforce, whereas an automated system can minimize the need for labor, resulting in substantial cost savings.

- Improved Egg Quality: Automated systems help maintain a consistent environment, ensuring the quality of eggs remains high.

According to a study published in the Journal of Animal Science, farms with automated egg collection systems reported a 20% increase in egg production compared to those relying on manual methods.

Key Features of an Automated Egg Collection System

| Feature | Description |

|---|---|

| Egg Trays | Customizable egg trays designed to accommodate the size and shape of eggs, ensuring optimal placement within the collection area. |

| Conveyor Belts | High-speed conveyor belts that transport eggs from the hen house to the collection point, reducing the need for manual handling. |

| Sorting Mechanisms | Advanced sorting systems that identify and remove cracked or abnormal eggs from the collection process. |

| Environmental Control | Integrated systems to monitor and control temperature, humidity, and CO2 levels within the collection area. |

Choosing the Right Automated Egg Collection System for Your Farm

When selecting an automated egg collection system, consider the following factors:

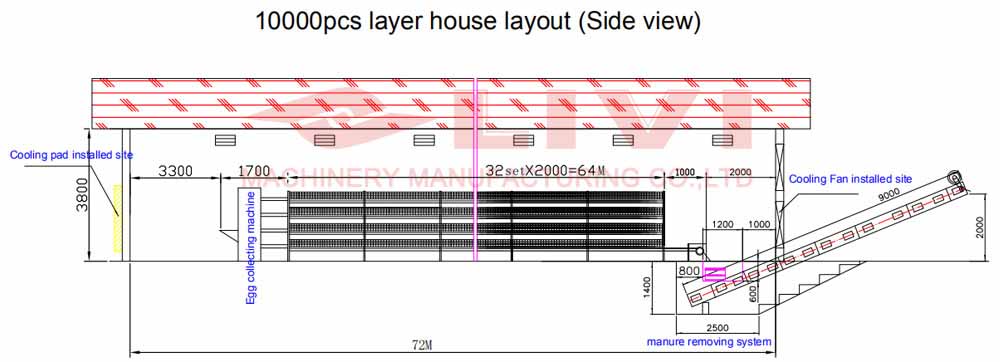

- Farm Size: Ensure the system’s capacity matches the size of your poultry operation.

- Egg Type: Different systems are designed for specific egg sizes and types, so choose one that fits your farm’s requirements.

- Reliability: Invest in a system with a proven track record and reliable performance.

- Service and Support: Look for manufacturers that offer comprehensive service and support, including training and maintenance.

Case Study: A Success Story

XYZ Poultry Farm, a medium-sized operation in the United States, recently implemented an automated egg collection system. Within the first year, the farm experienced a 30% increase in egg production, along with a reduction in labor costs by 25%. The farm’s owner, John Smith, stated, “The automated egg collection system has been a game-changer for our operation. It has improved our productivity, egg quality, and overall farm efficiency.”

For more information and a free chicken farm design plan, along with equipment pricing, contact us today!