Automatic Egg Collector for 200,000 Chickens in Kenya: A Comprehensive Guide

As the demand for eggs in Kenya continues to soar, modernizing poultry farming operations is crucial. One of the most significant advancements in the industry is the use of automatic egg collectors. This article delves into the necessity of such a system for a farm housing 200,000 chickens, providing insights into the benefits and key features to consider.

Why Automatic Egg Collectors are Essential for Large-scale Chicken Farms

Farms with over 200,000 chickens need efficient egg collection methods to maintain productivity and profitability. Manually collecting eggs can be time-consuming and labor-intensive, leading to potential losses. Automatic egg collectors, on the other hand, offer numerous benefits:

- Significant Time and Labor Savings: The system can collect eggs around the clock, minimizing downtime.

- Reduced Risk of Egg Breakage: Automated collection systems gently move eggs from the nests to storage, reducing the risk of damage.

- Enhanced Egg Quality: By minimizing human contact, the risk of cross-contamination is decreased, leading to better egg quality.

According to a study by the Kenya Poultry Development Programme, implementing an automatic egg collector can increase productivity by up to 20% on large-scale farms.

Key Features to Look for in an Automatic Egg Collector

Selecting the right automatic egg collector for a 200,000-chicken farm requires careful consideration of the following features:

- Capacity: Ensure the collector can handle the volume of eggs produced by 200,000 chickens.

- Automation Level: Look for a system that offers maximum automation to minimize human error and labor costs.

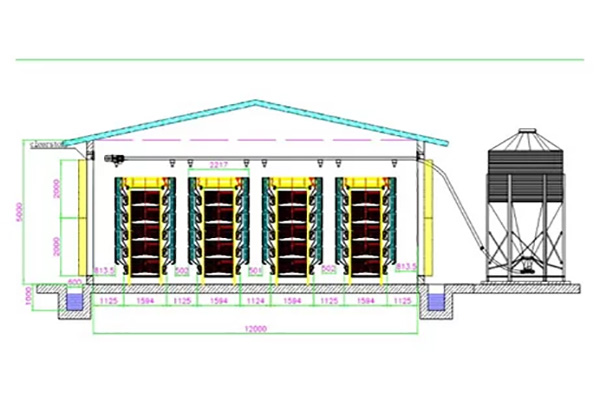

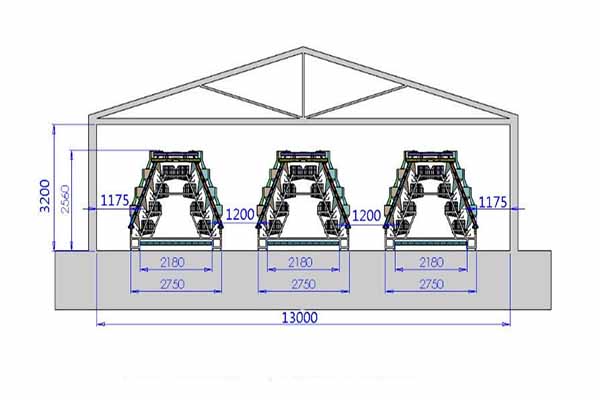

- Space Efficiency: Choose a model that fits within your existing farm layout and does not take up valuable space.

- Reliability and Maintenance: Select a collector with a proven track record of reliability and easy maintenance.

For example, the Livi Automatic Egg Collector has a capacity of up to 30,000 eggs per hour and is designed with a user-friendly interface and remote monitoring capabilities.

<img src="http://www.qualitychickenfarm.com/wp-content/uploads/2025/11/50000-layers -in-h-type-chicken-cage-3.jpg” alt=”inserted image”>

-in-h-type-chicken-cage-3.jpg” alt=”inserted image”>

Cost-Benefit Analysis of Automatic Egg Collectors

While the initial investment in an automatic egg collector may seem steep, the long-term benefits outweigh the costs. Consider the following factors:

- Reduction in Labor Costs: Automating the egg collection process reduces the need for additional labor, which can lead to significant savings.

- Increased Productivity: With a higher productivity rate, farms can meet the increasing demand for eggs more efficiently.

- Improved Egg Quality: The use of automatic collectors ensures higher-quality eggs, which can fetch better prices in the market.

As per a report by the Kenya Poultry Farmers Association, the cost of an automatic egg collector for a 200,000-chicken farm can range from $10,000 to $20,000. However, the savings on labor and increased productivity can offset this cost in a matter of months.

Conclusion

Investing in an automatic egg collector for a 200,000-chicken farm in Kenya is a strategic decision that can lead to increased profitability and productivity. By considering the right features and conducting a thorough cost-benefit analysis, farms can make informed decisions to enhance their operations.

For more information and to get a free poultry farming design and equipment quote from Livi Machinery, please leave a comment below. Our team of experts is ready to assist you in finding the perfect solution for your farm’s needs.