Automatic Manure Scraper for 200,000 Chickens in Kenya: Efficiency in Poultry Farming

Introduction

The poultry industry is rapidly growing in Kenya, with chicken farms increasingly aiming for higher productivity and better sanitation. With the expansion of farms comes the need for efficient manure management solutions. This article discusses the installation of an automatic manure scraper designed for a 200,000 chicken operation in Kenya, highlighting the benefits and potential return on investment.

Poultry waste management is critical in maintaining a healthy environment for chickens and reducing the risk of diseases. The automated manure scraper has become an essential tool for large-scale chicken farming, ensuring a clean and hygienic environment.

System Overview

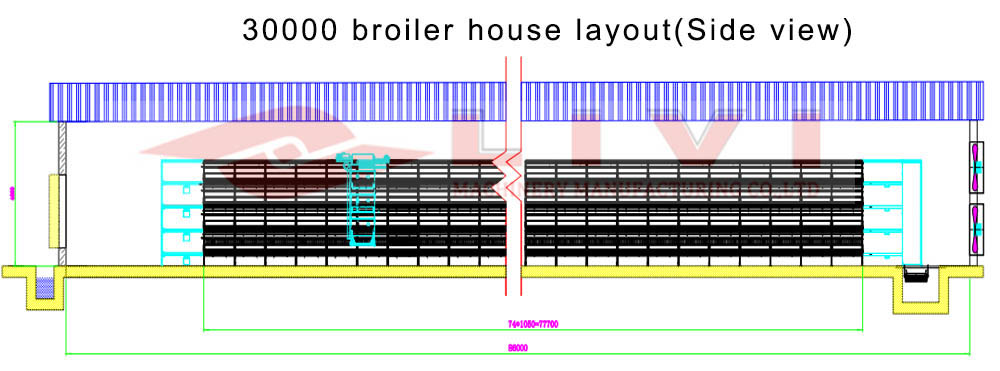

The automatic manure scraper is a state-of-the-art system that efficiently collects and removes waste from chicken houses. It is designed to handle a flock size of 200,000 chickens, with a throughput rate of up to 5,000 birds per hour.

- Continuous operation: The system runs 24/7, ensuring non-stop waste collection.

- Hygiene: Minimizes the risk of diseases caused by ammonia and bacteria in poultry manure.

- Space-saving: Compact design that takes up minimal floor space in the chicken house.

- Cost-effective: Reduces the labor cost associated with manual waste removal.

| System Feature | Description |

|---|---|

| Scraping Width | 3 meters |

| Chicken House Coverage | Up to 1,000 square meters |

| Scraping Speed | 1 to 2 meters per minute |

Return on Investment (ROI)

The initial investment in an automatic manure scraper might be substantial, but the long-term benefits are significant. Below are some of the factors contributing to the ROI:

- Improved animal health: By maintaining a clean environment, the incidence of diseases decreases, leading to fewer veterinary bills.

- Increased egg production: Hygienic conditions promote healthier chickens, which results in higher egg yields.

- Lower labor costs: Automated systems reduce the need for manual labor, thus saving on labor expenses.

- Compliance with regulations: Proper waste management helps comply with environmental regulations, reducing legal risks and fines.

The typical payback period for an  automatic manure scraper system ranges from 1.5 to 3 years, depending on the scale of operation and management practices.

automatic manure scraper system ranges from 1.5 to 3 years, depending on the scale of operation and management practices.

Conclusion

Investing in an automatic manure scraper for a 200,000 chicken farm in Kenya can greatly improve the efficiency of poultry operations. By ensuring a hygienic environment, it also enhances the well-being of the chickens, leading to better productivity and profitability.

Fo r potential clients interested in improving their chicken farming operations with our LIVI mechanical systems, we invite you to contact us for a free poultry farming design and equipment quote. Let us help you maximize your farm’s potential!

r potential clients interested in improving their chicken farming operations with our LIVI mechanical systems, we invite you to contact us for a free poultry farming design and equipment quote. Let us help you maximize your farm’s potential!