Battery Broiler Cage System for 60,000 Chickens in Pakistan: A Comprehensive Guide

Understanding the Battery Broiler Cage System

The battery broiler cage system is a highly efficient and controlled method for raising chickens. It provides a structured environment that maximizes space utilization and ensures the health and welfare of the birds. In Pakistan, where the demand for broiler meat is rapidly increasing, implementing such a system can be a game-changer for chicken farmers.

Designing the System for 60,000 Chickens

When planning a battery broiler cage system for 60,000 chickens, several factors need to be considered:

– Space Allocation: On average, each chicken requires about 0.5 square feet of space. For 60,000 chickens, a total space of approximately 30,000 square feet is necessary.

– Ventilation: Adequate ventilation is crucial to prevent heat stress and to maintain a healthy environment. The system should include ventilation fans and air curtains to ensure a controlled airflow.

– Cage Specifications: Cages should be designed with a floor space of around 2 square feet per chicken. This ensures that each bird has enough room to move and grow.

Key Components of the System

The following components are essential for a battery broiler cage system for 60,000 chickens:

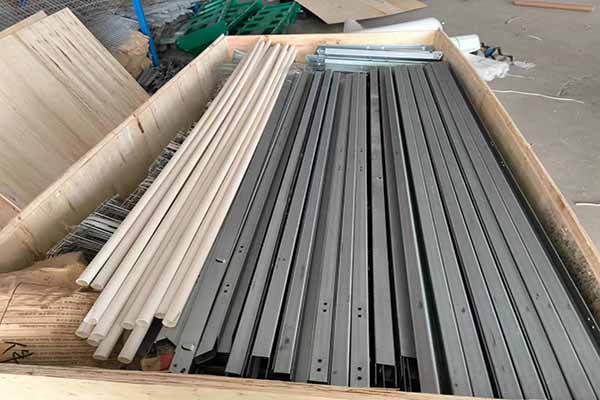

– Cages: High-quality, durable cages that are easy to clean and maintain.

– Feeding and Watering Systems: Automated feeding and watering systems to ensure constant access to food and water.

– Environmental Control Units: Systems to regulate temperature, humidity, and light, optimizing the growth conditions for the chickens.

Benefits of Implementing a Battery Broiler Cage System

– Increased Productivity: The system allows for faster growth and higher yields compared to traditional methods.

– Reduced Labor Costs: Automation reduces the need for manual labor, thereby reducing costs.

– Better Biosecurity: The enclosed system minimizes the risk of disease transmission.

Case Study: Successful Implementation in Pakistan

A recent project in Pakistan involved the installation of a battery broiler cage system for 60,000 chickens. The system was designed to include the following:

– 6000 Cages: Each holding 10 chickens.

– Automated Feeding and Watering Systems: To ensure a constant supply of feed and water.

– Environmental Control Units: To maintain optimal conditions for the chickens.

The results were impressive, with an average growth rate of 3.2 pounds per week and a survival rate of 98%.

Conclusion

Implementing a battery broiler cage system for 60,000 chickens in Pakistan can be a strategic move for any poultry farmer looking to increase productivity and efficiency. The key is to plan meticulously, considering all the necessary components and ensuring that the system is well-maintained.

Contact Us for Free Design and Quotation

Are you considering a battery broiler cage system for your farm? Contact LIVI Mechanical today for a free, customized design and equipment quotation. Our team of experts is ready to assist you in achieving success in the poultry industry.