Battery Cages Factory Cost Analysis: A Comprehensive Guide for Zambia’s Poultry Industry

Understanding the Cost Structure of Battery Cages in Zambia

The poultry industry in Zambia is rapidly growing, with an increasing demand for high-quality chicken production. Battery cages have become the preferred method for intensive poultry farming, ensuring optimal conditions for the birds. However, understanding the cost of setting up a battery cage factory in Zambia is crucial for both entrepreneurs and investors.

Below is a breakdown of the key factors influencing the factory cost of battery cages in Zambia.

1. Manufacturing Costs

1.1 Materials

- Metallic structures (steel, aluminum): The choice of material affects the durability and cost of the cages. Steel is more durable but can be more expensive.

- Plastic components: High-quality plastic components can enhance the hygiene and longevity of the cages.

1.2 Labor

The skilled labor required for the manufacturing process plays a significant role in determining the overall cost. In Zambia, the average hourly wage for skilled labor in the manufacturing sector is around $3 to $5.

2. Land and Infrastructure

2.1 Land acquisition

The cost of land in Zambia varies depending on the location. In urban areas, the price per square meter can range from $2 to $10.

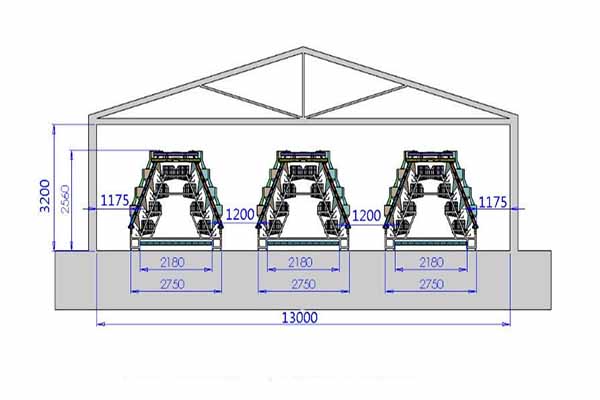

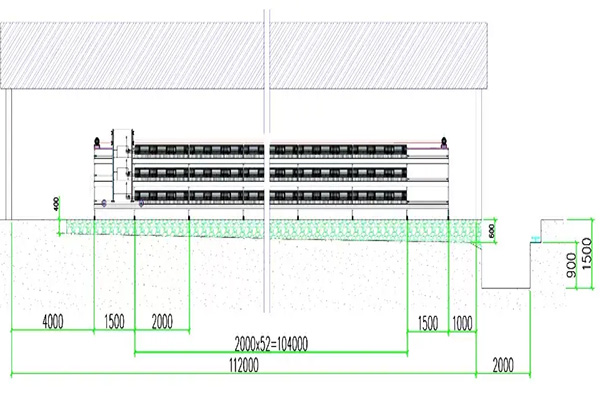

2.2 Building construction

The construction cost of a battery cage factory in Zambia ranges from $15 to $25 per square meter, depending on the quality of the materials and finishes used.

3. Operational Costs

3.1 Machinery and equipment

The cost of machinery and equipment varies depending on the scale of the factory. For a small-scale operation, the investment can range from $50,000 to $150,000.

3.2 Energy consumption

Battery cages require a consistent power supply. In Zambia, the average cost of electricity is around $0.15 to $0.20 per kilowatt-hour.

4. Regulatory Compliance and Certification

The cost of obtaining necessary licenses and certifications for operating a battery cage factory in Zambia can range from $1,000 to $5,000.

5. Market and Distribution

5.1 Market Research

Conducting market research to identify potential customers and analyze competition is essential. The cost of market research can range from $500 to $2,000.

5.2 Distribution Channels

The cost of establishing distribution channels, such as partnerships with local poultry farms and retailers, can range from $5,000 to $10,000.

Conclusion

Setting up a battery cage factory in Zambia involves various costs, with the total investment potentially ranging from $200,000 to $1,000,000, depending on the scale and quality of the factory. As the poultry industry continues to grow, understanding the cost structure is vital for making informed decisions.

For more information or to obtain a free poultry farming design and equipment quote, please leave a comment below or contact us at [email protected].