Broiler Cage Equipment for 120,000 Chickens: A Comprehensive Guide for Zambian Farms

As the poultry industry continues to grow in Zambia, large-scale broiler operations are becoming increasingly common. For farms aiming to house up to 120,000 chickens, investing in high-quality broiler cage equipment is crucial. This article will provide an overview of the key considerations and requirements for broiler cage equipment suitable for a farm of this size.

Understanding Broiler Cage Equipment

Broiler cage equipment is designed to provide optimal living conditions for broiler chickens. These systems typically include several components:

- Cages: The primary living space for chickens, designed to accommodate a specific number of birds per cage.

- Feeding Systems: Mechanisms for automatic feeding, ensuring consistent access to feed.

- Watering Systems: Automated systems to provide continuous access to clean water.

- Environmental Control Systems: Including heating, cooling, and ventilation to maintain ideal living conditions.

- Monitoring Systems: Equipment to track the health and performance of the chickens.

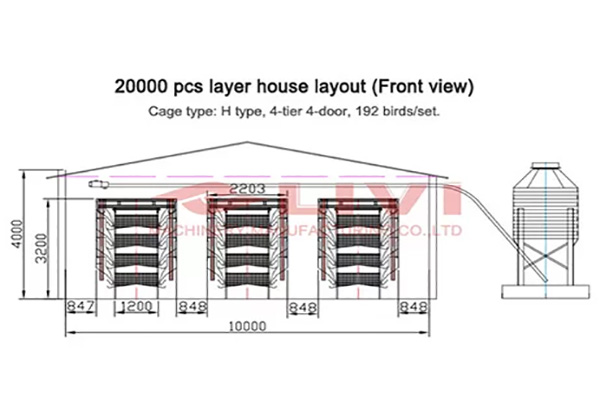

Key Considerations for 120,000 Chicken Broiler Cages

When planning for a broiler operation housing 120,000 chickens, several factors must be taken into account:

Space Requirements

Calculate the required space per chicken. For broiler chickens, this is typically around 0.3 square meters per bird. For 120,000 chickens, you will need approximately 36,000 square meters of space.

Cage Capacity

Choose the appropriate cage size to accommoda te the number of chickens. A standard broiler cage can hold around 15-20 chickens. For 120,000 chickens, you will need around 6,000-8,000 cages.

te the number of chickens. A standard broiler cage can hold around 15-20 chickens. For 120,000 chickens, you will need around 6,000-8,000 cages.

Automated Systems

Implementing automated feeding and watering systems will greatly improve efficiency and reduce labor costs. Consider systems that can handle large quantities of feed and water and maintain consistent access for the chickens.

Environmental Control

Invest in high-quality environmental control systems to ensure optimal living conditions for the chickens. This includes heating, cooling, and ventilation systems to maintain a stable temperature and humidity level.

Monitoring and Management

Install monitoring systems to track the health and performance of your chickens. This can include systems for temperature, humidity, and feed/water consumption. Regular monitoring will help identify and address any issues promptly.

Conclusion

Investing in high-quality broiler cage equipment for a farm housing 120,000 chickens is essential for success in the  poultry industry. By considering space requirements, cage capacity, automated systems, environmental control, and monitoring, you can create an efficient and profitable operation. For more information and a free chicken farming design and equipment quote, contact Livi Machinery today.

poultry industry. By considering space requirements, cage capacity, automated systems, environmental control, and monitoring, you can create an efficient and profitable operation. For more information and a free chicken farming design and equipment quote, contact Livi Machinery today.