Broiler Cage Feeder Automation: Revolutionizing Chicken Farm Efficiency

As the poultry industry continues to evolve, the adoption of automation technologies has become crucial for enhancing farm productivity and reducing costs. One of the most impactful innovations is the implementation of broiler cage feeder automation. This article explores the benefits of this technology and its implications for chicken farm operations.

The Importance of Automation in Broiler Farming

Broiler farming, which focuses on raising chickens for meat, is one of the fastest-growing segments of the poultry industry. With millions of broiler chickens produced annually, the efficiency and accuracy of feeding systems are of paramount importance.

According to the Global Broiler Culling report, around 40% of broiler chickens suffer from malnutrition or digestive disorders, which can be mitigated through precise automation in feeding.

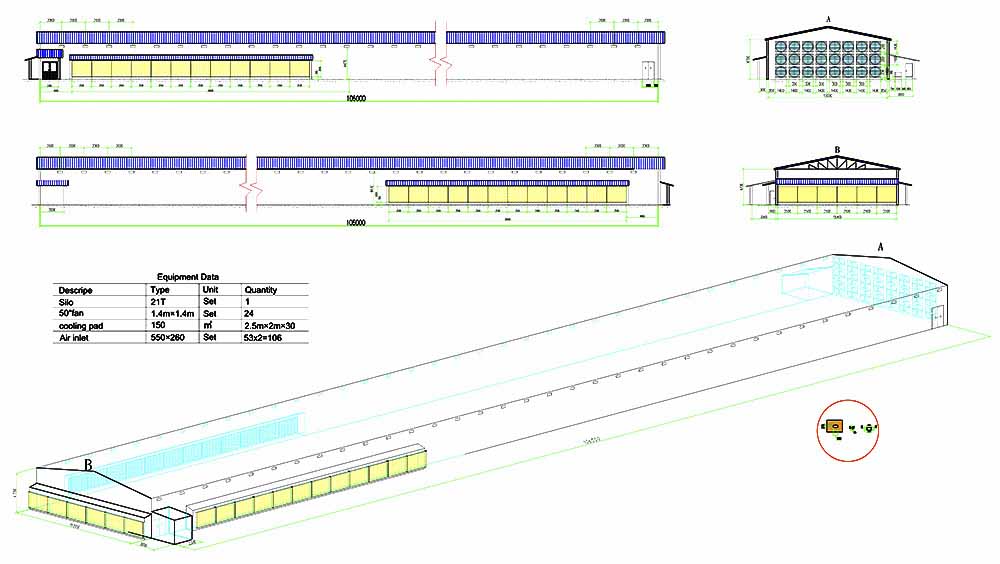

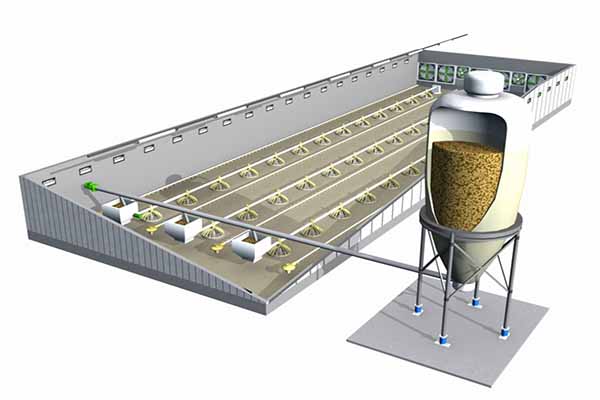

How Broiler Cage Feeder Automation Works

Broiler cage feeder automation systems are designed to deliver feed accurately and consistently to the chickens. These systems are typically equipped with sensors and software that optimize feed distribution based on the needs of the chickens and the farm’s operational parameters.

- Sensors: They monitor the feed level, water consumption, and health status of the chickens.

- Software: It analyzes the data to adjust feeding schedules and amounts to ensure optimal nutrition.

- Controllers: They execute the feeding commands, controlling the feed delivery mechanisms.

Benefits of Broiler Cage Feeder Automation

The adoption of broiler cage feeder automation offers several advantages:

- Improved Feed Conversion Rate: Automation leads to a more accurate feed distribution, reducing waste and improving the feed conversion rate.

- Enhanced Health: Automated feeding reduces the risk of overfeeding or underfeeding, contributing to better chicken health.

- Cost Savings: By reducing feed waste and optimizing health outcomes, farms can lower their operational costs.

- Environmental Impact: Automation decreases the need for labor, reducing the farm’s carbon footprint.

Data from the National Research Council (NRC) suggests that feed conversion rates can improve by up to 15% with the implementation of automation technologies.

Case Study: The Impact of Automation on a Large-Scale Chicken Farm

One of the largest chicken farms in the United States, with over 2 million broiler chickens, recently adopted a broiler cage feeder automation system. Within a year, the farm reported the following results:

| Parameter | Pre-Automation | Post-Automation |

|---|---|---|

| Feed Conversion Rate | 1.8:1 | 1.5:1 |

| Health Incidents | 300 per month | 50 per month |

| Operational Costs | $100,000 per month | $75,000 per month |

>

>