Chicken House Design Of 25000 Layers

livi Machinery provides chicken design design of 25000 layers for chicken farmer. Come to learn more about the information of poultry design!

Livi Machinery, in collaboration with a Philippines poultry farmer, has developed an innovative and efficient Chicken House design Of 25,000 layers chicken farming operation. This comprehensive design aims to maximize productivity, ensure animal welfare, and optimize operational efficiency.

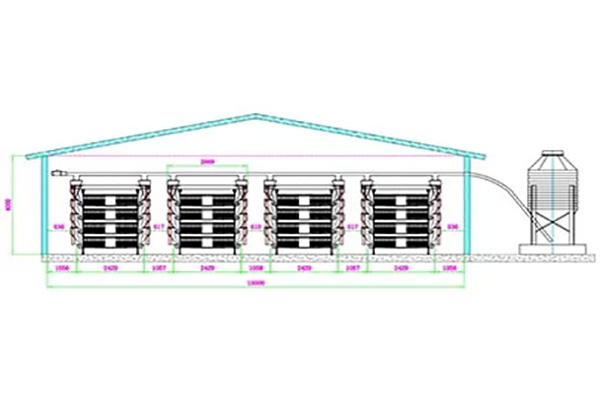

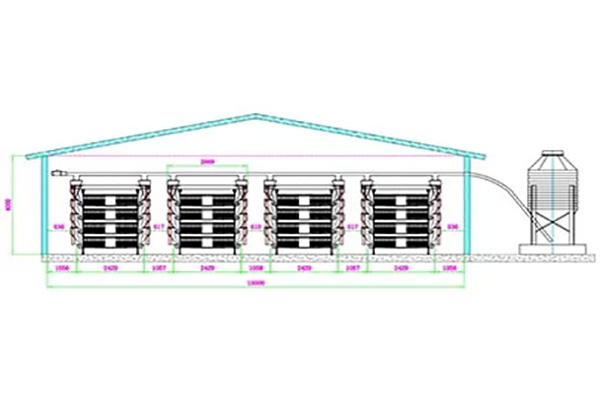

Chicken House Facility Layout

LivI Machinery proposes a well-thought-out facility layout to accommodate 25,000 layer chickens. The layout emphasizes proper spacing between chicken houses, feed storage, and processing areas to facilitate smooth operations.

Chicken House Design Of 25000 Layers

livi machinery recommends the use of H-type laying cage. A set of four-tiers H-type layer cage can raise 144 laying hens.

A customer in the Philippines who wants to raise 25,000 laying hens needs 174 sets of H-type laying hens.

Livi Machinery recommends state-of-the-art chicken houses equipped with climate control systems, ensuring optimal temperature, ventilation, and lighting conditions. The design incorporates advanced automation for feeding, watering, and egg collection, promoting efficiency and reducing labor requirements.

25000 layers Need Equipment

- Biosecurity Measures:

To safeguard the health of the flock, LivI Machinery incorporates stringent biosecurity measures. This includes controlled access points, foot baths, and isolation areas to prevent the spread of diseases. Additionally, a waste management system is integrated to maintain cleanliness and hygiene within the facility. - Feed and Nutrition:

LivI Machinery’s design includes a customized nutrition plan for the layers, taking into account their specific dietary requirements for optimal egg production. The facility will have dedicated areas for feed storage and preparation, ensuring a consistent and well-balanced diet for the chickens. - Egg Collection and Processing:

Efficient egg collection is vital for maximizing productivity. LivI Machinery incorporates a modern egg collection and processing system that minimizes the risk of breakage and ensures the delivery of high-quality eggs. The design also includes facilities for egg grading, cleaning, and packaging. - Waste Management:

LivI Machinery prioritizes environmentally sustainable practices, and thus, the design includes an effective waste management system. This involves the proper disposal and recycling of waste, contributing to a more eco-friendly and sustainable poultry farming operation. - Monitoring and Control Systems:

To enhance operational control, LivI Machinery integrates advanced monitoring systems. These systems include real-time data on temperature, humidity, feed consumption, and egg production. This information allows for proactive decision-making and ensures the overall health and well-being of the flock.

LivI Machinery’s chicken house design of 25,000 layers chicken facility in the Philippines represents a holistic approach to poultry farming. By incorporating cutting-edge technology, biosecurity measures, and sustainable practices, this design aims to create a model poultry farm that prioritizes efficiency, animal welfare, and environmental responsibility.

livi Machinery provides chicken design design to chicken farmers free of charge. Contact us to learn more about the information of poultry cages!