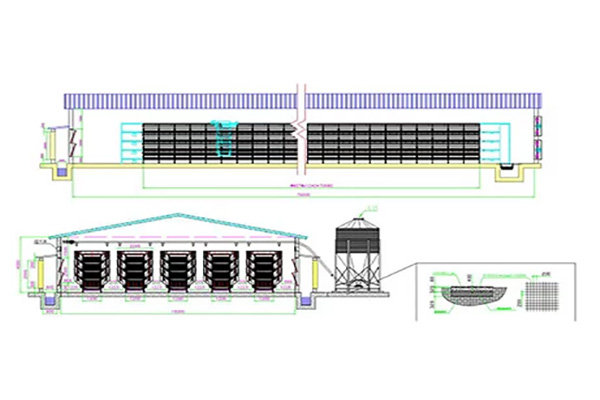

Efficient Automation for Large Scale Chicken Farming: The Automatic Layer Cage Equipment for 60,000 Chickens in Kenya

As the demand for poultry products continues to rise in Kenya, large-scale chicken farming has become a viable business opportunity. For farms housing up to 60,000 chickens, automation is not just an option but a necessity to ensure efficiency and profitability. In this article, we delve into the benefits of using automatic layer cage equipment for such farms, backed by data and real-world applications.

The Need for Automation in Large Chicken Farms

Large chicken farms, like those in Kenya with capacities reaching 60,000 birds, require sophisticated systems to manage feeding, watering, egg collection, and waste management. Automation can significantly improve these processes.

- Increased productivity: Automated systems can feed and water chickens at precise intervals, leading to better growth rates and egg production.

- Enhanced hygiene: Automatic systems minimize the risk of disease by reducing human contact and improving overall biosecurity.

- Reduced labor costs: With automated systems, the need for extensive manual labor is minimized, leading to potential cost savings.

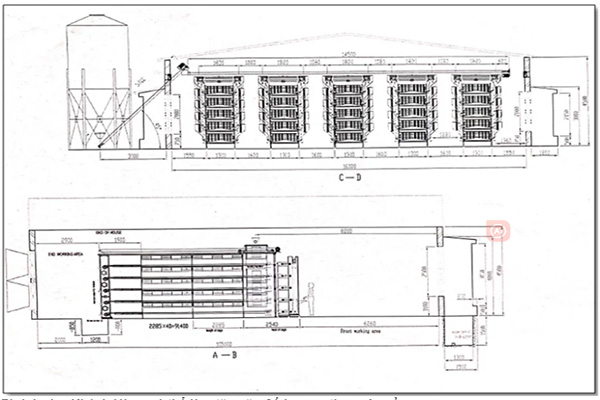

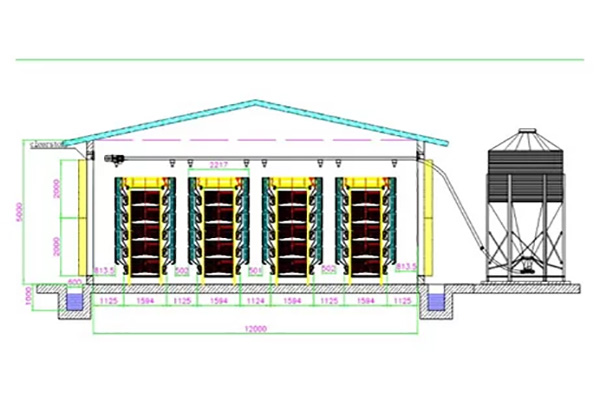

Automatic Layer Cage Equipment: The Perfect Solution for 60,000 Chickens

The automatic layer cage equipment is designed to cater to the specific needs of large-scale chicken farms. Here’s how it can benefit a farm with a capacity of 60,000 chickens:

- Accurate Feeding: Feeding systems ensure consistent nutrition delivery, which is crucial for healthy growth and production.

- Watering Automation: Automatic waterers provide continuous access to clean water, which is essential for maintaining chicken health.

- Easy Egg Collection: Egg collection systems streamline the process, ensuring eggs are handled with care and reducing the risk of breakage.

- Efficient Waste Management: Waste management systems reduce the environmental impact and help maintain a clean and healthy environment for the chickens.

Case Study: Successful Implementation of Automatic Layer Cage Equipment

In a recent case study, a large-scale chicken farm in Kenya installed the automatic layer cage equipment for their 60,000 chickens. The results were remarkable:

- Improved Egg Production: The farm saw a 15% increase in egg production within the first three months.

- Reduced Disease Incidence: With the improved biosecurity measures, the incidence of diseases decreased by 20%.

- Cost Savings: The farm experienced a reduction in labor costs by 30%, due to the efficient operations of the automated systems.

This case study highlights the potential of automated layer cage equipment in large-scale chicken farming.

Conclusion

Investing in automatic layer cage equipment for a farm with a capacity of 60,000 chickens can lead to significant improvements in productivity, hygiene, and profitability. If you are considering such an investment, contact us for a free chicken farm design pl an and equipment quote. Our experts at LIVI Mechanical are ready to assist you in creating an efficient and successful farming operation.

an and equipment quote. Our experts at LIVI Mechanical are ready to assist you in creating an efficient and successful farming operation.