Egg Collection System for 500,000 Chickens in Nigeria: A Comprehensive Guide

As the poultry industry in Nigeria continues to grow, the demand for efficient egg collection systems has become increasingly important. For a farm housing 500,000 chickens, an effective egg collection system is crucial for maintaining productivity and reducing labor costs. This article will explore the key aspects of an egg collection system for a 500,000 chicken operation in Nigeria.

Key Components of an Egg Collection System

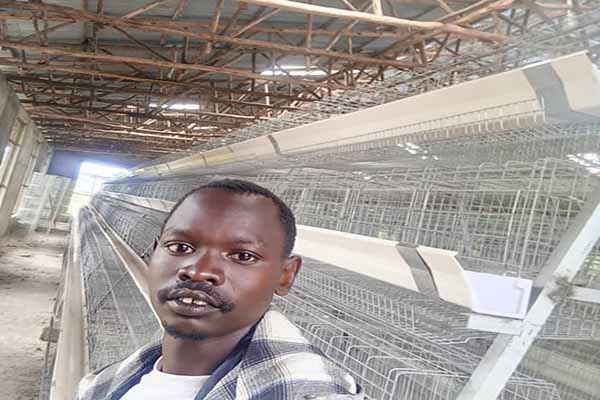

- Egg Laying Houses: These are designed to accommodate the chickens and provide a comfortable environment for laying eggs. The size of the laying houses should be proportional to the number of chickens, ensuring ample space for movement and laying.

- Egg Collection Equipment: This includes conveyors, collection bins, and sorting systems. The equipment should be capable of handling the high volume of eggs produced daily.

- Sanitization Systems: To maintain hygiene and prevent the spread of diseases, an effective sanitization system is essential. This includes regular cleaning and disinfection of the laying houses and collection equipment.

- Automated Sorting and Packaging: To optimize efficiency, an automated system for sorting and packaging eggs is recommended. This minimizes manual labor and ensures that eggs are properly packaged for sale.

Designing an Egg  Collection System for 500,000 Chickens

Collection System for 500,000 Chickens

When designing an egg collection system for a 500,000 chicken operation, several factors must be considered:

- Capacity: The system must be able to handle the daily egg production of 500,000 chickens, which is approximately 2.5 million eggs per day.

- Efficiency: The system should be designed to minimize downtime and maximize productivity.

- Cost-Effectiveness: The system should be cost-effective to install and maintain.

- Scalability: The system should be designed to accommodate future expansion if needed.

For a 500,000 chicken operation, a system with the following specifications is recommended:

| Component | Specification |

|---|---|

| Egg Laying Houses | 100 houses, each housing 5,000 chickens |

| Egg Collection Conveyors | 10 conveyors, each with a capacity of 250,000 eggs per hour |

| Collection Bins | 20 bins, each with a capacity of 50,000 eggs |

| Sanitization System | Automated cleaning and disinfection system for laying houses and conveyors |

| Sorting and Packaging Equipment | Automated sorting and packaging line with a capacity of 500,000 eggs per hour |

Implementing such a system requires careful planning and expertise. It is recommended to consult with professionals who specialize in poultry farming and egg collection systems.

Benefits of an Efficient Egg Collection System

- Increased productivity due to reduced labor costs

- Improved egg quality and safety

- Enhanced farm hygiene and disease prevention

- Streamlined egg handling and packaging process

For more information on designing an egg collection system for your 500,000 chicken operation in Nigeria, please leave a comment below or contact us for a free, no-obligation consultation. We at Livi Mechanical are committed to providing innovative solutions for the poultry industry.