Egg Layer Cage System for 120,000 Hens in Zambia: A Comprehensive Guide

As the poultry industry continues to expand in Zambia, providing a reliable and efficient egg layer cage system for a large-scale operation like 120,000 hens is crucial. This article delves into the essential aspects of designing and implementing an optimal cage system for such a high-density operation.

Understanding the Requirements for a 120,000 Hen Egg Layer Cage System

When dealing with a massive number of hens, it’s essential to consider the following factors:

- Space Allocation: Each hen requires adequate space to move and exhibit natural behaviors. Typically, this is around 0.6 square meters per hen.

- Airflow and Ventilation: Ensuring proper airflow is critical for maintaining a healthy environment. A system that provides at least 20 cubic meters of air per hen is recommended.

- Feeding and Watering: A well-designed system should include automatic feeders and waterers that can cater to the high demand of 120,000 hens.

- Health Monitoring: Regular health checks are vital. The system should allow for easy access to individual hens for health assessments.

With these factors in mind, let’s explore the key components of a 120,000 hen egg layer cage system in Zambia.

Key Components of a La rge-Scale Egg Layer Cage System

rge-Scale Egg Layer Cage System

The following components are essential for a 120,000 hen egg layer cage system in Zambia:

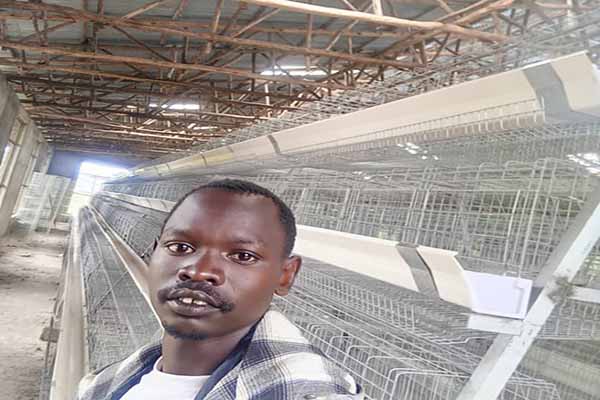

1. Cages and Racks

The choice of cages and racks is crucial for the comfort and well-being of the hens. Modern cage systems typically use plastic or metal cages with a multi-tiered design. This allows for efficient use of space while providing individual nesting areas.

2. Feeding System

For a large-scale operation, an automated feeding system is necessary. These systems can be adjusted to feed the correct amount of feed at predetermined times, ensuring consistent nutrition for the hens.

3. Watering System

Similar to the feeding system, an automated watering system is essential for providing fresh water to the hens. This system should be designed to prevent contamination an d ensure that water is accessible to all hens at all times.

d ensure that water is accessible to all hens at all times.

4. Egg Collection Mechanism

An efficient egg collection mechanism is necessary to minimize manual handling and reduce the risk of broken eggs. Automated egg collection systems are often used in large-scale operations.

5. Environmental Control System

This system regulates temperature, humidity, and air quality to create an optimal environment for the hens. In Zambia, this is particularly important due to the diverse climate and potential temperature fluctuations.

Benefits of Implementing an Egg Layer Cage System for 120,000 Hens

Implementing a high-density egg layer cage system for 120,000 hens in Zambia offers several benefits:

- Increased Efficiency: Automated systems reduce labor costs and improve overall operational efficiency.

- Improved Egg Quality: Properly managed systems ensure that hens are well-nourished and healthy, leading to better egg quality.

- Reduced Waste: Automated systems minimize waste and reduce the environmental impact of poultry operations.

With these benefits in mind, it’s clear that a well-designed egg layer cage system is essential for any large-scale poultry operation in Zambia.

Conclusion

Implementing an egg layer cage system for 120,000 hens in Zambia requires careful planning and consideration of key factors. By choosing the right components and adhering to best practices, poultry farmers and investors can create a successful and efficient operation.

For more information on how to design and implement a system for your operation, feel free to leave a comment below or contact us for a free, customized design and equipment quotation from LIVI Mechanical.