Fully Automated Poultry Farm Equipment: The Future of Chicken Farming

Introduction

With the ever-growing demand for poultry products, the efficiency and automation of poultry farming have become crucial. Implementing fully automated poultry farm equipment can lead to significant improvements in productivity, animal welfare, and cost savings. In this article, we will explore the various types of fully automated poultry farm equipment available in the market today.

Key Components of Fully Automated Poultry Farm Equipment

- Automatic Feeding Systems: These systems ensure accurate and timely feeding of birds, leading to better growth rates and overall health. Automatic feeding systems can save time and reduce labor costs.

- Automatic Watering Systems: Similar to feeding systems, automatic watering systems maintain optimal water consumption, promoting animal health and preventing diseases.

- Automatic Egg Collection Systems: Fully automated egg collection systems reduce the risk of eggs being contaminated and ensure efficient collection, saving time and labor.

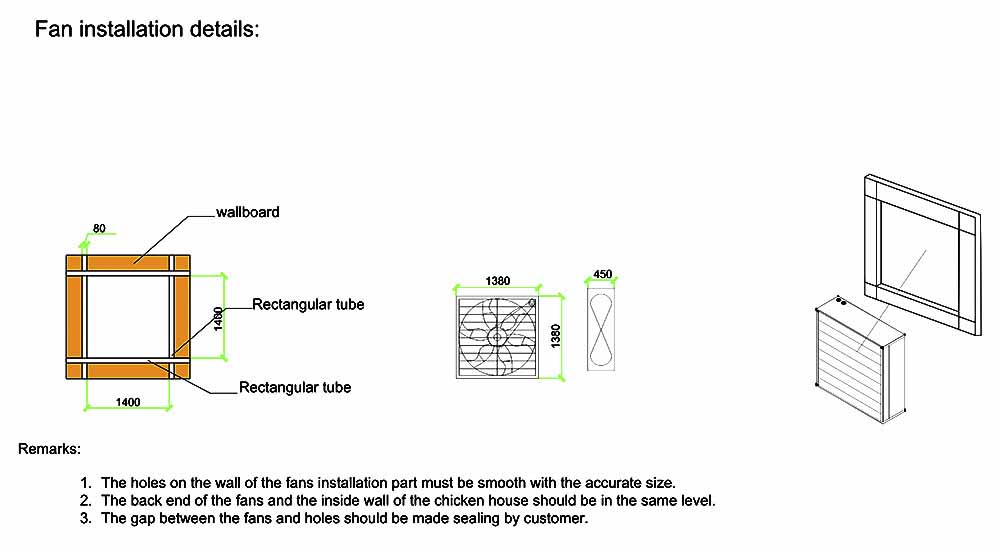

- Climate Control Systems: Maintaining a consistent environment is crucial for optimal poultry growth. Automated climate control systems regulate temperature, humidity, and ventilation, providing an ideal living environment for birds.

- Health Monitoring Systems: Modern poultry farm equipment often includes health monitoring systems that can track bird behavior and detect early signs of illness. This enables prompt treatment and prevents disease outbreaks.

Data shows that farms using automated equipment have a 10-15% higher production rate compared to those relying on traditional methods. Furthermore, the use of automated systems can reduce labor costs by up to 30%, according to recent studies.

Why Choose Fully Automated Poultry Farm Equipment?

Investing in fully automated poultry farm equipment can provide several benefits:

- Increased production and productivity

- Improved animal welfare

- Reduced labor costs

- Enhanced biosecurity and disease prevention

- Higher profit margins

Table 1: Comparison of traditional and automated poultry farming systems

| Aspect | Traditional | Automated |

|---|---|---|

| Production Rate | 60-70% of birds | 80-90% of birds |

| Labor Costs | $1,200 – $1,500 per employee | $800 – $1,000 per employee |

| Health Monitoring | Manual observations | Automated tracking systems |

Conclusion

As the poultry industry continues to evolve, investing in fully automated poultry farm equipment is essential for staying competitive. The benefits of increased productivity, improved animal welfare, and reduced costs make automated systems an attractive option for poultry farm owners and investors.

Are you interested in transforming your poultry farm with our cutting-edge automated equipment? Contact us today t o get a free poultry farm design plan and equipment quote. Let LIVI MECHANICAL help you pave the way for a successful and sustainable poultry farming business.

o get a free poultry farm design plan and equipment quote. Let LIVI MECHANICAL help you pave the way for a successful and sustainable poultry farming business.