Layer Battery Cage System for 180,000 Chickens in Togo: A Comprehensive Guide

As the poultry industry continues to grow, especially in countries like Togo, efficient and scalable farming systems are crucial. One such system is the layer battery cage system, which has proven to be highly effective for managing large flocks. In this article, we will delve into the details of a layer battery cage system designed for 180,000 chickens in Togo, discussing its benefits, setup, and maintenance.

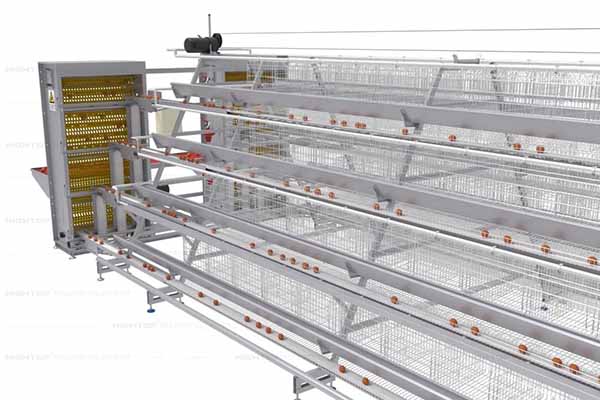

Overview of the System

The layer battery cage system is a highly automated and efficient method for housing laying hens. It is designed to maximize space utilization, reduce labor costs, and improve overall chicken welfare. In the case of the system for 180,000 chickens in Togo, the following features were implemented:

- Cage Capacity: The system can accommodate up to 180,000 chickens.

- Cage Dimensions: Each cage is designed to house 10 chickens, ensuring optimal space for movement and growth.

- Automated Feeding and Watering: The system includes automated feeders and waterers to ensure the chickens receive a consistent and balanced diet.

- Environmental Control: The system is equipped with climate control mechanisms to maintain optimal temperature and humidity levels.

- Manure Management: Automated manure removal systems are integrated to keep the environment clean and hygienic.

Table 1: Key Features of the Layer Battery Cage System for 180,000 Chickens in Togo

| Feature | Description |

|---|---|

| Cage Capacity | Up to 180,000 chickens |

| Cage Dimensions | 10 chickens per cage |

| Automated Feeding and Watering | Ensures consistent and balanced diet |

| Environmental Control | Maintains optimal temperature and humidity levels |

| Manure Management | Automated manure removal systems |

>

>