Layer Battery Cage System for 200,000 Chickens in Nigeria: An Efficient Solution

In the fast-growing poultry industry of Nigeria, an effective and scalable layer battery cage system is essential for achieving high productivity and profitability. With the aim of accommodating up to 200,000 chickens, a robust and well-designed system is a must. In this article, we explore the key features and benefits of implementing a layer battery cage system for a large-scale poultry farm in Nigeria.

What is a Layer Battery Cage System?

A layer battery cage system is a highly efficient method of housing laying hens. It consists of several tiers of battery cages, which are stacked vertically. This allows for maximum utilization of space, reduc ing the need for a large farm area. Each cage is designed to accommodate one hen, ensuring proper space and facilities for the birds.

ing the need for a large farm area. Each cage is designed to accommodate one hen, ensuring proper space and facilities for the birds.

Key Features of a Layer Battery Cage System for 200,000 Chickens

- Optimized Space Utilization: The system allows for a high-density housing of chickens, making it suitable for large-scale operations.

- Health and Hygiene: Battery cages are designed to prevent the spread of diseases and maintain high levels of hygiene.

- Automated Feeding and Watering: Systems can be equipped with automated feeding and watering mechanisms, ensuring that chickens receive a consistent diet and fresh water.

- Temperature Control: The system can be designed to maintain optimal temperatures for the chickens, promoting their growth and well-being.

- Easy Monitoring: With a battery cage system, farm managers can easily monitor the health and productivity of the chickens.

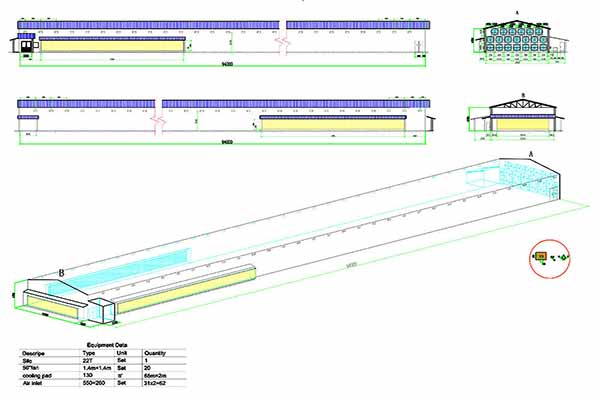

Case Study: 200,000 Chicken Layer Battery Cage System in Nigeria

One of our clients in Nigeria has successfully implemented a layer battery cage system for 200,000 chickens. The farm has reported the following benefits:

- Increased Production: The farm has seen a significant increase in egg production, thanks to the efficient system.

- Reduced Costs: By optimizing space utilization and reducing the need for additional labor, the farm has been able to cut down on costs.

- Improved Hygiene: The battery cage system has helped in maintaining high levels of hygiene, resulting in healthier chickens.

Below is a table showing the key specifications of the system:

| Feature | Specification |

|---|---|

| Number of Layers | 200,000 |

| Cage Dimensions | 1m x 0.6m |

| Number of Cages per Tier | 40 |

| Total Number of Tiers | 50 |

| Feeding System | Automated |

| Watering System | Automated |

Conclusion

Investing in a layer battery cage system for a large-scale poultry farm in Nigeria can offer numerous benefits, including increased production, reduced costs, and impr oved hygiene. At LIVI Machinery, we specialize in providing tailored solutions for poultry farms. If you are considering implementing a layer battery cage system for your farm, please leave a comment below or contact us for a free consultation and equipment quotation.

oved hygiene. At LIVI Machinery, we specialize in providing tailored solutions for poultry farms. If you are considering implementing a layer battery cage system for your farm, please leave a comment below or contact us for a free consultation and equipment quotation.