Layer Battery Cage System for 30,000 Chickens in Uganda: A Comprehensive Guide

As the poultry industry in Uganda continues to grow, efficient and scalable solutions are crucial for successful chicken farming. One such solution is the implementation of a layer battery cage system designed for a capacity of 30,000 chickens. This article will delve into the intricacies of such a system, highlighting its benefits, requirements, and potential challenges.

What is a Layer Battery Cage System?

A layer battery cage system is an innovative method of housing laying hens. It involves stacking multiple tiers of cages vertically, allowing for efficient use of space and easy management of the flock. Each cage typically houses up to 5-7 hens, providing them with a comfortable living environment.

Benefits of the Layer Battery Cage System for 30,000 Chickens

- Space Efficiency: The vertical stacking of cages maximizes space utilization, which is particularly beneficial for farms with limited land.

- Easy Management: Cages are easy to clean and sanitize, reducing the risk of disease outbreaks.

- Increased Egg Production: Properly managed layer battery cages can lead to higher egg production rates, resulting in better financial returns.

- Health Monitoring: The confined space allows for easier monitoring of the flock’s health and well-being.

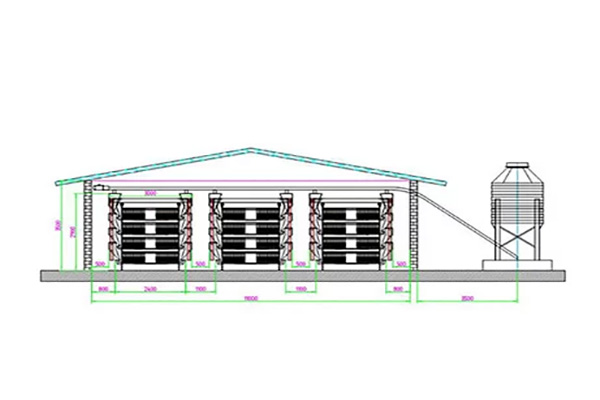

Design Considerations for a 30,000 Chicken Layer Battery Cage System

Designing a layer battery cage system for 30,000 chickens requires careful planning and consideration of several factors:

- Cage Specifications: The dimensions, materials, and design of the cages should meet the specific needs of the hens and the farm’s objectives.

- Environmental Control: Adequate ventilation and temperature regulation are essential for the health and productivity of the chickens.

- Water and Feed Supply: A reliable water and feed supply system is crucial to ensure the hens receive proper nutrition and hydration.

- Manpower and Training: Sufficient skilled labor and proper training are necessary to maintain and manage the system effectively.

Cost and Return on Investment

The cost of implementing a layer battery cage system for 30,000 chickens can vary depending on the scale, location, and quality of materials used. However, the system can lead to significant cost savings and improved productivity, resulting in a favorable return on investment.

| Initial Investment | Operating Costs | Expected Egg Production | Estimated Return on Investment |

|---|---|---|---|

| $50,000 | $20,000 | 60,000 eggs/month | 2 years |

Conclusion

Investing in a layer battery cage system for 30,000 chickens in Uganda can be a strategic move for poultry farmers and investors looking to maximize space, improve productivity, and ensure a healthy flock. By carefully considering design, cost, and maintenance, farmers can create a sustainable and profitable operation.

For more information and a free chicken farming design and equipment quote, please leave a comment below or contact us directly. Our team of experts is ready to assist you in transforming your poultry business.