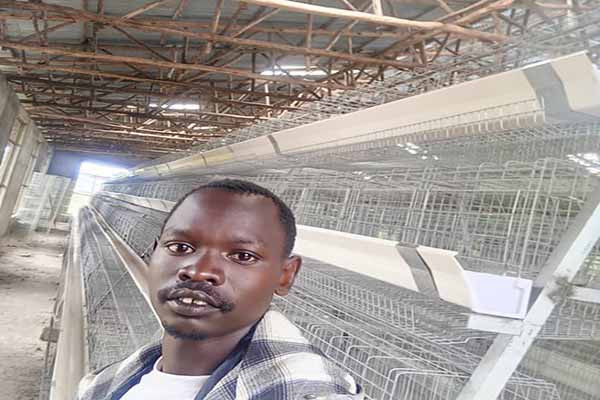

Layer Battery Cage System for 50,000 Chickens in Zambia: A Comprehensive Guide

Introduction to Layer Battery Cages

The layer battery cage system is a modern method for raising chickens, particularly for egg production. It offers efficient use of space and promotes healthier and more productive chickens. In Zambia, with its growing poultry industry, such systems are becoming increasingly popular.

Key Benefits of the System for 50,000 Chickens

- Space Efficiency: The battery cage system maximizes space utilization, allowing for the accommodation of up to 50,000 chickens in a relatively small area.

- Health and Welfare: Properly designed battery cages reduce the risk of injury among chickens and maintain hygiene standards.

- Increased Productivity: Chickens in battery cages tend to lay more eggs per day compared to those in free-range settings.

- Ease of Management: The system simplifies flock management, allowing for better monitoring and control of health, feeding, and egg collection.

According to a study by the Zambia National Commercial Bank (ZNCB), farms using the battery cage system see a 20% increase in egg production over free-range systems.

Components of a Layer Battery Cage System

| Component | Description |

|---|---|

| Cages | Individually locked cages for each bird, designed for comfortable perching, roosting, and laying. |

| Feeding Systems | Automatic feeders that provide a consistent supply of food, ensuring balanced nutrition. |

| Watering Systems | Access to fresh water throughout the day, essential for chicken health. |

| Environmental Control Units | Systems to maintain optimal temperature and humidity, enhancing productivity and reducing stress. |

Implementation and Maintenance

When setting up a battery cage system for 50,000 chickens, it’s crucial to follow best practices:

- Design: Plan the layout meticulously to ensure ease of movement for the chickens and personnel.

- Construction: Use high-quality materials that withstand wear and tear and comply with animal welfare standards.

- Installation: Employ experienced professionals for installation to ensure proper functionality.

- Training: Train staff in cage management, handling procedures, and health monitoring.

- Regular Maintenance: Schedule regular checks and maintenance to keep the system in optimal condition.

Contact Us for a Free Design and Quotation

At Livi Machinery, we specialize in providing comprehensive solutions for poultry farming, in cluding layer battery cage systems. Contact us today for a free design consultation and equipment quotation tailored to your specific needs.

cluding layer battery cage systems. Contact us today for a free design consultation and equipment quotation tailored to your specific needs.

Ready to transform your farm? Reach out to us at [[email protected]](mailto:[email protected]) or call us at +264 975634567.