Maximizing Efficiency in Poultry Farming with Automatic Egg Grading Machines

Introduction

As the poultry industry continues to evolve, modern technology plays a crucial role in improving efficiency and profitability. One such technology is the automatic egg grading machine, which has revolutionized the way eggs are handled and sorted in chicken farms. This article delves into the benefits of implementing an automatic egg grading system and its impact on the poultry farming industry.

Benefits of Automatic Egg Grading Machines

- Consistent Quality Control: These machines ensure uniform grading of eggs based on their size, weight, and shell quality, which helps maintain a high standard of egg quality.

- Increased Efficiency: Automation reduces the time and labor required for egg grading, allowing farmers to focus on other aspects of their operations.

- Cost Reduction: By minimizing manual labor, the cost of egg grading can be significantly reduced.

- Improved Productivity: Faster sorting processes lead to increased overall productivity on the farm.

According to a study by the International Journal of Poul try Science, farms that implemented automatic egg grading machines saw a 20% increase in productivity compared to those that relied on manual sorting.

try Science, farms that implemented automatic egg grading machines saw a 20% increase in productivity compared to those that relied on manual sorting.

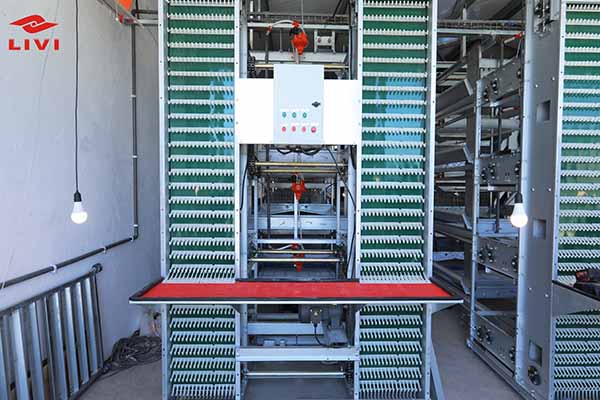

How Does an Automatic Egg Grading Machine Work?

An automatic egg grading machine uses advanced technology to sort eggs based on their physical characteristics. The process typically involves the following steps:

- Eggs are fed into the machine through a hopper.

- The eggs are scanned using high-resolution cameras that capture their dimensions and other attributes.

- The data is analyzed by a sophisticated software program that categorizes the eggs into different grades.

- The eggs are then automatically placed into bins or trays corresponding to their grade.

Investment Return on Automatic Egg Grading Machines

While the initial investment in an automatic egg grading machine can be substantial, the long-term benefits often outweigh the costs. Consider the following:

| Cost Aspect | Annual Cost |

|---|---|

| Manual Egg Grading Labor | $20,000 |

| Automatic Egg Grading Machine | $40,000 (initial investment) |

| Increased Egg Sales (due to better quality) | $30,000 |

With these figures, the automatic egg grading machine pays for itself within a year and continues to provide savings and increased revenue over time.

Conclusion

Investing in an automatic egg grading machine can significantly enhance the efficiency and profitability of a poultry farm. By ensuring consistent quality control, red ucing labor costs, and improving productivity, these machines are a valuable asset for any poultry farmer looking to stay competitive in the industry.

ucing labor costs, and improving productivity, these machines are a valuable asset for any poultry farmer looking to stay competitive in the industry.

For more information on how an automatic egg grading machine can benefit your farm, please leave a comment below or contact us directly for a free poultry farming design plan and equipment quotation.