Optimal Broiler Cages for 250,000 Chickens in Togo: A Comprehensive Guide

Broiler cage systems are a critical component in large-scale poultry farming. For a facility housing 250,000 chickens in Togo, it’s essential to have a system that maximizes efficiency, hygiene, and growth rates. In this article, we’ll explore the key considerations and requirements for broiler cages tailored for such a large operation.

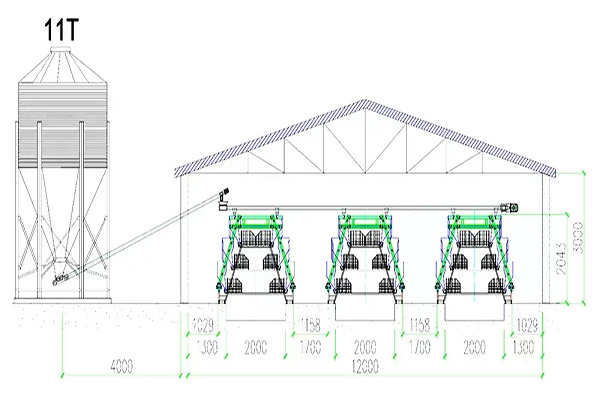

Design and Capacity

A broiler cage for 250,000 chickens requires careful planning to ensure sufficient space and ventilation. Typically, each chicken should have at least 0.5 square feet of space. This translates to a total area of 125,000 square feet. The design should accommodate the number of birds without compromising their health or welfare.

Example:

- 250,000 chickens x 0.5 square feet per chicken = 125,000 square feet of space needed

Material and Durability

Broiler cages must be made from high-quality, corrosion-resistant materials to withstand the demands of a large-scale operation. Steel or aluminum are popular choices due to their durability and ease of cleaning.

Airflow and Temperature Control

Proper airflow is crucial for maintaining a healthy environment. Cages should be designed with a system that allows for adequate air exchange without causing drafts. Additionally, temperature control is essential, with a target range of 70-75°F for optimal growth rates.

Feeding and Watering Systems

The feeding and watering systems should be efficient and reliable. Automatic feeding systems can distribute feed accurately and evenly, while nipple waterers or cup waterers ensure continuous access to water.

Manure Management

Efficient manure removal is essential to maintain hygiene and prevent disease. Slatted floors are commonly used in large-scale operations, as they allow manure to fall through to a collection system.

Cost and ROI

Investing in high-quality broiler cages for a 250,000-chicken operation can be expensive. However, the long-term benefits, including increased productivity and reduced health issues, can lead to a significant return on investment (ROI).

Case Study

One successful installation in Togo featured a system designed to house 250,000 chickens. The facility utilized high-quality steel cages, automated feeding and watering systems, and a robust manure management plan. As a result, the operation saw a 15% increase in growth rates and a 30% decrease in disease incidents.

Table: System Specifications

| Component | Specification |

|---|---|

| Cage Material | High-quality steel |

| Space per Chicken | 0.5 square feet |

| Airflow | 100 cubic feet per minute per chicken |

| Temperature Control | 70-75°F |

Are you considering a similar project for your poultry farm in Togo? Contact LIVI Machinery today for a free design consultation and equipment quotation.