Optimal Full Poultry Farm Equipment for a 200,000 Chicken Operation in Nigeria

As the poultry industry in Nigeria continues to grow, investing in the right equipment for a full-scale farm with 200,000 chickens is crucial for efficiency and profitability. This article outlines the essential equipment needed for such an operation, along with considerations for selecting the best solutions.

Key Equipment for a 200,000 Chicken Farm in Nigeria

- Brooder Houses: These are vital for the initial stage of chick development. A well-ventilated and temperature-controlled environment is necessary to ensure healthy growth. For a 200,000 chicken farm, you would need approximately 10-12 brooder houses.

- Feeders and Waterers: Automatic feeders and waterers can greatly increase efficiency. For this scale of operation, consider high-capacity systems that can serve up to 20,000 chickens at a time.

- Manure Management Systems: Proper waste management is crucial for health and hygiene. A solid manure removal system, such as a scraper or conveyor belt, is essential.

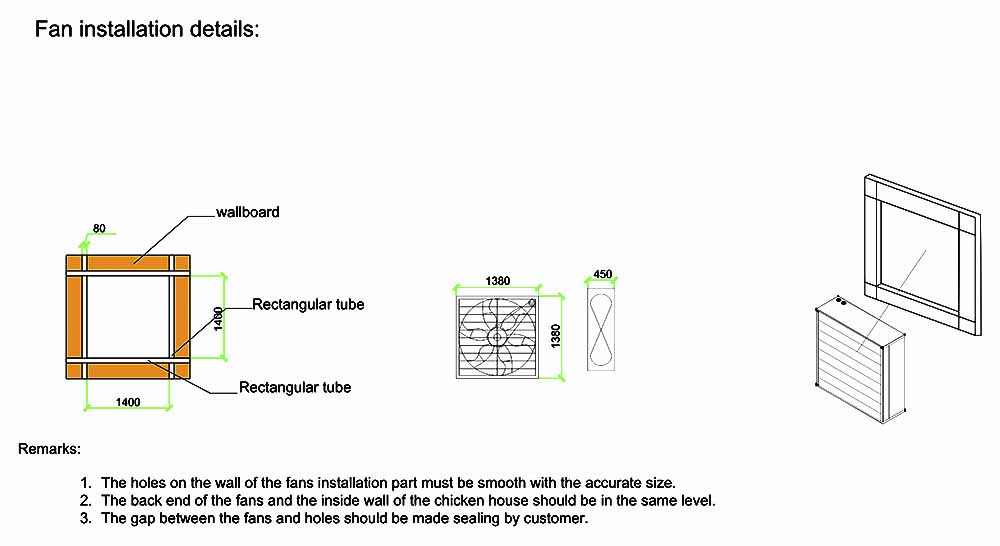

- Environmental Control Systems: These systems help maintain optimal temperature and humidity levels in the poultry houses, reducing stress on the birds and improving production.

- Vaccination and Health Monitoring Equipment: Regular health checks and vaccinations are critical. Equipment like thermometers, scales, and vaccination machines are necessary for this purpose.

According to a study by the Federal Ministry of Agriculture and Rural Development, Nigeria’s poultry industry is projected to grow at an annual rate of 5-6% over the next decade. Investing in high-quality equipment is key to staying competitive in this market.

Cost and Efficiency Considerations

When planning a full poultry farm for 200,000 chickens, it’s important to consider both initial investment costs and long-term operational efficiency. Here are some factors to keep in mind:

- Initial Investment: The total cost can range from $500,000 to $1 million, depending on the quality and brand of equipment.

- Energy Efficiency: Choose energy-efficient equipment to reduce operational costs. For example, LED lighting and automated heating systems can save on energy bills.

- Warranty and Maintenance: Ensure that the equipment comes

with a comprehensive warranty and that maintenance services are readily available.

with a comprehensive warranty and that maintenance services are readily available.

Table 1: Estimated Costs for Key Equipment

| Equipment | Estimated Cost (USD) |

|---|---|

| Brooder Houses | $20,000 – $30,000 |

| Feeders and Waterers | $15,000 – $20,000 |

| Manure Management Systems | $10,000 – $15,000 |

| Environmental Control Systems | $25,000 – $35,000 |

| Vaccination and Health Monitoring Equipment | $5,000 – $10,000 |

Investing in quality equipment can lead to higher production yields, reduced downtime, and improved overall farm performance.

Contact Us for a Free Poultry Farm Design and Equipment Quote

Are you ready to take your poultry farm to the next level? Contact us today for a free, comprehensive design of your full poultry farm equipment setup and a detailed equipment quote tailored to your needs. Our expert team at LIVI Mechanical is here to help you achieve success in the Nigerian poultry industry.

Email: [email protected]

Phone: +234 701 234 5678