Optimizing Chicken Battery Cage Systems for 80,000 Chickens in Nigeria

Introduction

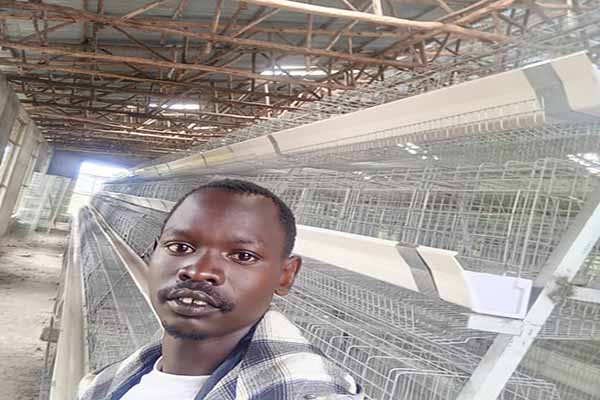

The Nigerian poultry industry has witnessed significant growth, with a large number of chicken farms emerging. One key aspect of successful poultry farming is the implementation of an efficient chicken battery cage system. This article discusses the design and considerations for a chicken battery cage system tailored for a farm housing 80,000 chickens in Nigeria.

System Design for 80,000 Chickens

Designing a chicken battery cage system for 80,000 chickens requires careful planning to ensure the health, welfare, and productivity of the flock. Here are some crucial factors to consider:

- Space Allocation: Allocate at least 0.7 square meters per chicken to provide adequate space for movement and reduce stress.

- Cage Layout: Opt for a single-tier or multi-tier system based on the farm’s layout and the chickens’ growth stages.

- Airflow: Ensure proper ventilation to maintain optimal temperature and humidity levels, which is crucial for chicken health.

- Feeding and Watering: Install automated feeding and watering systems to reduce labor costs and ensure the flock receives a balanced diet.

- Manure Management: Implement a solid manure collection system to keep the environment clean and prevent disease outbreaks.

| System Component | Description | Recommended Quantity |

|---|---|---|

| Cages | High-quality steel battery cages designed for layer chickens | 80,000 cages |

| Ventilation Fans | Automated fans for temperature control | 20 fans |

| Feeding Systems | Automated feeding systems to ensure uniform feed distribution | 2 systems |

| Watering Systems | Automated watering systems with drinker lines | 2 systems |

| Manure Collection System | Manure belt conveyors for efficient waste management | 1 system |

</secti on>

on>

Benefits of a Proper Chicken Battery Cage System

A well-designed chicken battery cage system offers several benefits:

- Improved Welfare: Enhanced space allocation and better ventilation contribute to improved chicken welfare.

- Increased Productivity: Automated feeding and watering systems can lead to more consistent egg production.

- Reduced Costs: By minimizing labor requirements and disease outbreaks, costs can be significantly reduced.

- Environmental friendliness: Proper waste management reduces environmental impact.

Conclusion

Implementing a high-quality chicken battery cage system for 80,000 chickens in Nigeria is crucial for the success of a poultry farm. With careful planning and attention to detail, farmers  can ensure their flock’s health, welfare, and productivity. For a free chicken farm design and equipment quote, please contact us at Livi Machinery.

can ensure their flock’s health, welfare, and productivity. For a free chicken farm design and equipment quote, please contact us at Livi Machinery.