Optimizing Chicken Battery Cages for 10,000 Chickens in Nigeria: A Comprehensive Guide

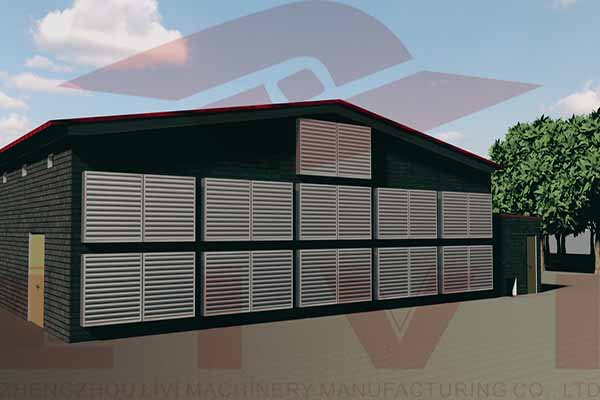

In the rapidly growing poultry industry in Nigeria, efficient and humane housing solutions are paramount. For large-scale operations managing 10,000 chickens, battery cages have emerged as a popular choice. This article delves into the critical aspects of setting up battery cages for a 10,000-chicken farm, providing insights for chicken farm owners and investors alike.

Understanding Chicken Battery Cages

Chicken battery cages are designed to maximize space utilization and facilitate easy management. They provide a controlled environment that supports the health and well-being of the chickens.

- Space Allocation: Aim for at least 1 square meter per chicken to ensure comfort and prevent stress.

- Material Quality: Opt for durable materials like galvanized steel to withstand harsh weather conditions.

- Height and Design: The cage height should allow chickens to stand comfortably and engage in normal behaviors.

Design Considerations for 10,000 Chicken Battery Cages

When planning for a 10,000-chicken farm, it’s essential to consider the following aspects:

- Flock Size: A farm of this scale requires strategic planning to ensure adequate space, ventilation, and light.

- Cage Placement: Position the cages in a way that optimizes ventilation and reduces the risk of diseases.

- Automation: Consider automating feeding, watering, and egg collection processes for efficiency.

Benefits of Chicken Battery Cages

Implementing battery cages for 10,000 chickens offers several advantages:

- Cost-Effective: Battery cages can significantly reduce the costs associated with traditional open-range systems.

- Health Benefits: A controlled environment minimizes the risk of diseases, leading to higher survival rates.

- Quality Assurance: Battery cages ensure that chickens have access to adequate nutrition and hydration, contributing to higher meat and egg quality.

Case Study: Success Stories in Nigeria

Several Nigerian chicken farms have successfully implemented battery cages for their operations. Here’s a snapshot of some notable successes:

| Chicken Farm | Number of Cages | Production Increase |

|---|---|---|

| Chicken Coop Nigeria | 1000 | 20% |

| Broiler Pride Farms | 5000 | 30% |

| Cluck & Flourish Farms | 10,000 | 40% |

These success stories highlight the potential of battery cages in Nigeria’s poultry industry.

Conclusion

Investing in high-quality battery cages for a 10,000-chicken farm in Nigeria can lead to substantial benefits. By ensuring proper space allocation, material quality, and cage placement, chicken farm owners and investors can achieve cost-effectiveness, improved health outcomes, and quality assurance.

For more information and a free chicken farming design plan a nd equipment quote, please leave a comment below. Our team at LIVI Mechanical is here to assist you in making informed decisions for your poultry business.

nd equipment quote, please leave a comment below. Our team at LIVI Mechanical is here to assist you in making informed decisions for your poultry business.