Optimizing Chicken Battery Cages for 400,000 Chickens in Zambia

Understanding the Scale of Commercial Chicken Farming in Zambia

Commercial chicken farming in Zambia is experiencing significant growth, with an increasing number of large-scale operations. One such operation involves the housing of 400,000 chickens in battery cages. This article delves into the essential considerations for setting up an efficient and humane system for such a large number of birds.

The efficient management of 400,000 chickens in battery cages requires careful planning and the adoption of modern, humane practices. Here’s a breakdown of the key factors to consider:

Key Considerations for Large-Scale Chicken Battery Cages

- Cage Design

- Airflow and Ventilation

- Water and Feeding Systems

- Health Management

- Space Allocation

Cage Design

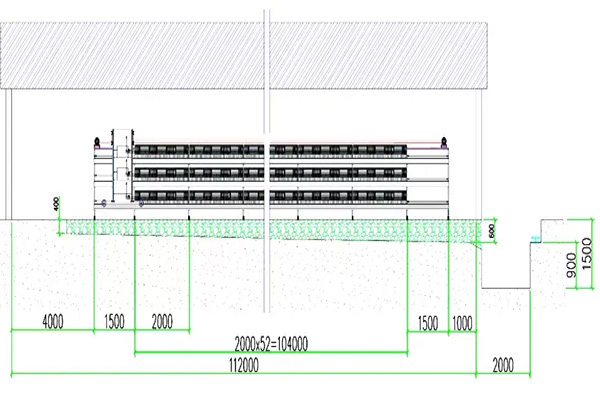

For a farm housing 400,000 chickens, the cage design needs to be robust and easy to maintain. Opt for durable materials that can withstand the rigors of a large-scale operation.

| Feature | Description |

|---|---|

| Material | Galvanized steel for rust resistance and durability |

| Dimensions | Ensure cages are of appropriate size to accommodate chickens comfortably |

| Entrance Design | Secure and easily accessible for routine checks and cleaning |

Airflow and Ventilation

Proper ventilation is crucial for maintaining good health in a densely populated poultry environment.

- Airflow Rate: Aim for an airflow rate of 1 cubic meter per bird per hour.

- Location: Place ventilation openings strategically to minimize drafts and temperature fluctuations.

- Heating Systems: Consider installing heating systems to maintain optimal conditions during colder months.

Water and Feeding Systems

Automated feeding and watering systems are essential for efficient operation and hygiene.

- Water System: Invest in a reliable water supply and distribution system to prevent contamination and ensure consistent access.

- Feeding System: Automated feeders should be spaced appropriately to avoid overcrowding and ensure equal access to feed.

Health Management

Maintaining the health of 400,000 chickens requires a comprehensive biosecurity plan and regular health checks.

- Biosecurity: Implement strict protocols to prevent the introduction of diseases.

- Regular Health Checks: Schedule weekly health screenings and promptly address any issues.

- Vaccination Programs: Follow a stringent vaccination schedule to protect against common poultry diseases.

Space Allocation

Each chicken requires adequate space to move around, which impacts the cage size and layout.

- Cage Size

- Calculate the space per chicken based on their breed and stage of growth.

- Standardize cage dimensions for consistency in the layout.

- Layout Design

- Plan the layout to maximize the use of space and minimize stress on the chickens.

- Ensure the layout facilitates easy movement of equipment and personnel.

In conclusion, managing 400,000 chickens in battery cages in Zambia requires careful consideration of cage design, airflow, feedin g systems, health management, and space allocation. By adhering to these guidelines, you can create an efficient, humane, and profitable operation.

g systems, health management, and space allocation. By adhering to these guidelines, you can create an efficient, humane, and profitable operation.

If you’re looking to optimize your chicken battery cages or need professional advice, feel free to leave a comment below or contact us directly for a free, tailored chicken farming design and equipment quotation from LIVI Machinery.

feel free to leave a comment below or contact us directly for a free, tailored chicken farming design and equipment quotation from LIVI Machinery.