Optimizing Chicken Cage Design for Maximum Ventilation: A Guide for Poultry Farmers

Effective ventilation in chicken cages is crucial for the health and productivity of poultry. This article delves into the design principles that maximize ventilation while ensuring animal welfare and efficiency in the poultry industry.

Understanding the Importance of Ventilation

Proper ventilation not only enhances the quality of life for chickens but also reduces the risk of respiratory diseases and improves egg production. According to the National Research Council (NRC), adequate air exchange rates should be maintained to ensure a comfortable environment for poultry.

Key Design Principles for Maximum Ventilation

- Location and Orientation: Positioning the cages in a way that takes advantage of natural airflow can significantly improve ventilation. South-facing orientations are often preferred due to the natural convection of air.

- Perimeter Ventilation: Placing vents along the perimeter of the cage allows for a more uniform distribution of air. This can be achieved through the use of louvers or vents designed to control the flow of air.

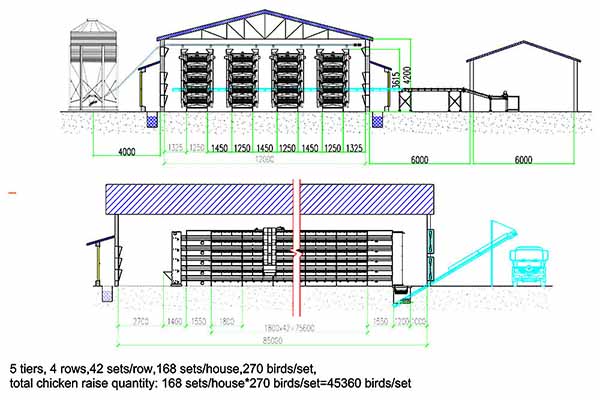

- Height and Space: Higher cages with increased space between rows promote better air circulation. The ideal cage height is often between 2.1 to 2.4 meters, with a minimum of 0.6 meters between rows.

- Materials: Using permeable materials for the cage walls can enhance air flow. For instance, perforated metal or ventilated panels are suitable options.

- Automated Systems: Incorporating automated ventilation systems can optimize air exchange rates based on the specific needs of the chickens, such as during hot weather or at night.

Case Study: Ventilation Efficiency in Chicken Cages

Let’s consider a case study where a modern poultry farm implemented a ventilation system based on the above principles. The farm saw a 15% increase in egg production and a 30% reduction in respiratory disease cases within the first year.

| Parameter | Before Implementation | After Implementation |

|---|---|---|

| Air Exchange Rate (per hour) | 1.5 | 2.2 |

| Egg Production (per bird) | 300 eggs/year | 345 eggs/year |

| Respiratory Disease Cases | 150 cases/year | 50 cases/year |

This case study demonstrates the tangible benefits of implementing a well-designed ventilation system in chicken cages.

Conclusion

Investing in an efficient chicken cage design for maximum ventilation can yield significant benefits for poultry farmers. By followin g the principles outlined in this article, farmers can create a healthier and more productive environment for their chickens.

g the principles outlined in this article, farmers can create a healthier and more productive environment for their chickens.

For more information on optimizing your chicken cage design and to receive a free quote on our Liv-i Mechanical ventilation systems, please leave a comment below or contact us directly.