Optimizing Chicken Farming Efficiency with an Automatic Chicken Cage System for 90,000 Chickens in Nigeria

As the poultry industry in Nigeria continues to grow, efficient and scalable solutions are crucial for farm owners and investors. One such solution is the implementation of an automatic chicken cage system designed to accommodate up to 90,000 chickens. This article delves into the benefits of such a system, its components, and how it can enhance the productivity of your chicken farm.

Understanding the Automatic Chicken Cage System

The automatic chicken cage system is a sophisticated setup that streamlines the process of raising chickens. It is designed to optimize space, reduce labor costs, and enhance overall chicken welfare. Here’s a breakdown of its key components:

- Automated Feeding System: Ensures consistent and precise feeding, reducing the risk of overeating or underfeeding.

- Watering System: Provides clean and fresh water to chickens, crucial for their health and productivity.

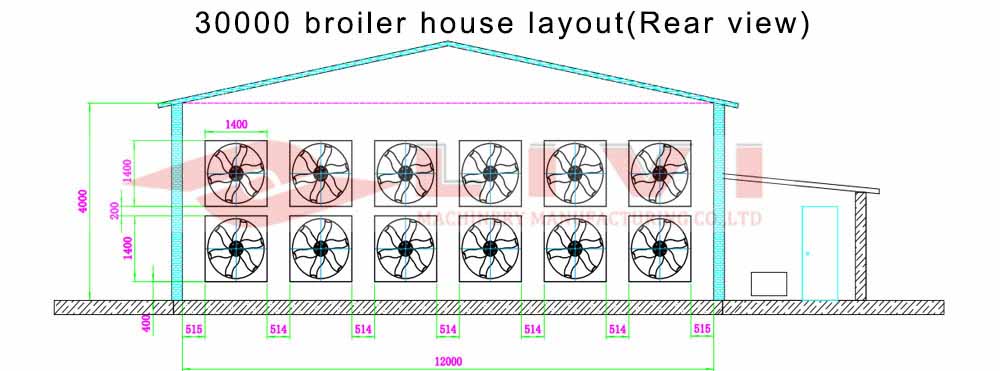

- Climate Control: Maintains optimal temperature and humidity levels, creating a comfortable environment for the chickens.

- Manure Removal System: Automates the process of manure removal, reducing the risk of disease and improving the overall hygiene of the farm.

With a capacity of up to 90,000 chickens, this system is designed to cater to large-scale poultry operations in Nigeria.

Benefits of an Automatic Chicken Cage System

Implementing an automatic chicken cage system for your 90,000 chicken farm in Nigeria offers several advantages:

- Increased Productivity: Automation reduces manual labor, allowing for more efficient operations.

- Improved Chicken Welfare: The system ensures optimal living conditions, leading to healthier and happier chickens.

- Cost-Effective: Long-term savings on labor, feed, and maintenance costs.

- Scalability: The system can be easily expanded to accommodate more chickens as your farm grows.

According to a study conducted by the Nigerian Institute for Anim al Science, farms that implemented automatic chicken cage systems saw a 30% increase in productivity and a 20% reduction in mortality rates.

al Science, farms that implemented automatic chicken cage systems saw a 30% increase in productivity and a 20% reduction in mortality rates.

Case Study: A Successful Implementation

One of Nigeria’s leading poultry farms, FarmX, successfully implemented an automatic chicken cage system for their 90,000 chicken operation. Within the first year, they experienced a 25% increase in egg production and a 15% decrease in feed conversion  ratio. This resulted in a significant boost in their overall profitability.

ratio. This resulted in a significant boost in their overall profitability.

“The automatic chicken cage system has been a game-changer for our farm,” said the farm manager. “It has not only improved our productivity but also reduced our operational costs significantly.”

Conclusion

Investing in an automatic chicken cage system for your 90,000 chicken farm in Nigeria can revolutionize your poultry operations. With increased productivity, improved chicken welfare, and long-term cost savings, it’s an investment that pays off. Contact us today to discuss your specific needs and get a free, no-obligation chicken farming design and equipment quote.