Optimizing Chicken Farming with Layer Battery Cage Systems for 400,000 Chickens in Zambia

Introduction to Layer Battery Cage Systems

In the modern poultry industry, the implementation of layer battery cage systems has revolutionized the way chickens are raised. These systems offer a highly efficient and humane way to house and manage laying hens, ensuring optimal productivity. In Zambia, where the demand for chicken meat and eggs continues to grow, such systems are increasingly becoming a staple in commercial chicken farming.

Benefits of Layer Battery Cage Systems

- Enhanced Egg Production: Battery cages provide an optimal environment for laying hens, leading to higher egg production rates.

- Reduced Disease Incidence: With better sanitation and controlled conditions, the incidence of diseases among birds is significantly lower.

- Space Efficiency: Layer battery cage systems are designed to maximize space utilization, making them ideal for large-scale chicken farming operations like the one in Zambia aiming to house 400,000 chickens.

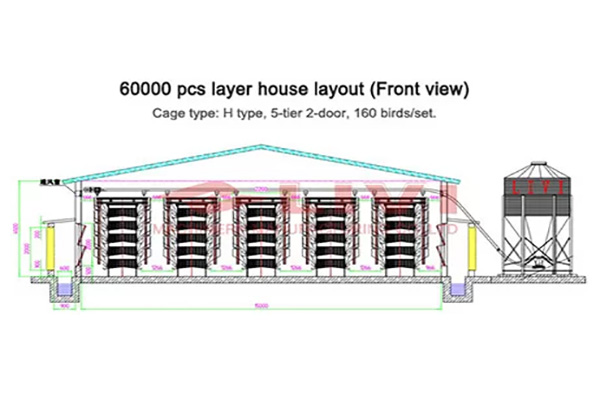

Designing a Layer Battery Cage System for 400,000 Chickens

Designing a layer battery cage system for a farm with 400,000 chickens requires careful planning and consideration of various factors:

| Factor | Requirement |

|---|---|

| Number of Battery Cages | Approximately 2,000 to 2,500 cages for 400,000 chickens, depending on cage size and spacing. |

| Cage Design | Standardized, with features like a feeding trough, nesting area, and ventilation systems. |

| Space Allocation | Ensure each cage has adequate space for the chickens to move around comfortably. |

| Environmental Control | Install automated systems for temperature, humidity, and lighting control. |

Case Study: Successful Implementation in Zambia

A leading poultry farm in Zambia successfully implemented a layer battery cage system for 400,000 chickens. The project included the following components:

- 2,300 battery cages

- State-of-the-art environmental control systems

- Automated feeding and water systems

- Regular maintenance and training for farm staff

The result was a 15% increase in egg production and a significant reduction in disease outbreaks.

Conclusion

Investing in a layer battery cage system for a 400,000-chicken farm in Zambia is a strategic move towards maximizing productivity and profitability. With careful planning and implementation, such a system can lead to substantial improvements in egg production, disease control, and overall farm efficiency.

For more information on designing and implementing a layer battery cage system for your farm, please feel free to leave a comment or contact us for a free, customized poultry farm design and equipment quotation.