Optimizing Chicken Farming with Layer Battery Cage Systems for 60,000 Chickens in Togo

As the demand for poultry continues to rise in Togo, efficient and modern farming practices are crucial for success. This article delves into the benefits of implementing a layer battery cage system for a capacity of 60,000 chickens, focusing on factors that contribute to higher productivity and better welfare.

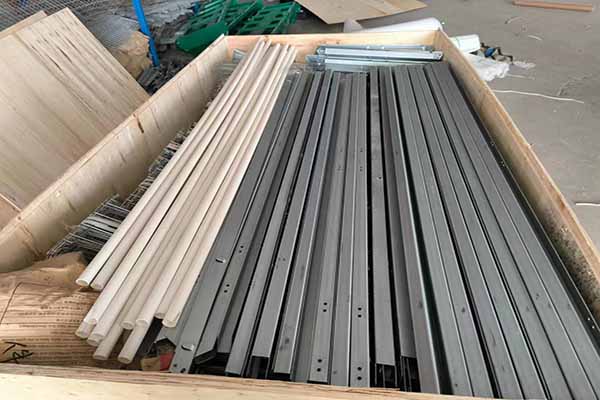

Understanding Layer Battery Cage Systems

A layer battery cage system is a highly automated and efficient method of housing laying hens. It provides a controlled environment, minimizing the risk of diseases and ensuring optimal egg production. Here’s a breakdown of its key features:

- Space Efficiency: Each cage is designed to accommodate one bird, ensuring ample space for movement and preventing overcrowding.

- Sanitation: With easy access for cleaning, the system helps maintain hygiene and reduces the likelihood of infections.

- Feeding and Watering: Automated feeders and drinkers ensure consistent nutrition and water supply, further enhancing productivity.

- Environmental Control: The system allows for precise control of temperature, humidity, and lighting, creating ideal conditions for egg production.

The Benefits of a Layer Battery Cage System for 60,000 Chickens in Togo

Implementing a layer battery cage system for a capacity of 60,000 chickens in Togo offers numerous advantages:

- Increased Productivity: Studies have shown that battery cage systems can increase egg production by up to 20% compared to traditional methods.

- Reduced Disease Outbreaks: The controlled environment and easy access for cleaning minimize the risk of diseases, resulting in healthier birds and lower mortality rates.

- Improved Egg Quality: The system promotes better egg quality through consistent nutrition and a controlled environment.

- Lower Operating Costs: Automated systems reduce labor costs and minimize waste, leading to higher profitability.

According to a report by the Togolese Poultry Association, a layer battery cage system for 60,000 chickens can produce an estimated 15,000,000 eggs annually, generating significant revenue for the farm.

Case Study: A Successful Layer Battery Cage System in Togo

One of Togo’s leading poultry farms has successfully implemented a layer battery cage system for 60,000 chickens. The farm owner, Mr. Kofi Togbe, shares his insights:

“The layer battery cage system has been a game-changer for our farm. It has improved our productivity, egg quality, and overall profitability. We couldn’t be happier with the results.”

Conclusion

Investing in a layer battery cage system for 60,000 chickens in Togo is a strategic move for poultry farmers and investors. It ensures higher productivity, better welfare, and lower operating costs, leading to a sustainable and profitable business.

Are you considering a layer battery cage system for your farm? Contact us for a free, professional design and equipment quotation. We’re here to help you achieve success in the poultry industry.