Optimizing Commercial Poultry Cage Systems for 300,000 Chickens in Kenya

With the increasing demand for poultry products in Kenya, commercial poultry farming has become a lucrative business venture. To cater to the growing industry, a comprehensive commercial poultry cage system is essential. In this article, we will explore the requirements for a 300,000 chicken capacity system and highlight the key components necessary for its successful implementation.

System Requirements for 300,000 Chickens

- Space Allocation: Approximately 0.6 square meters per bird is recommended.

- Environmental Control: Temperature, humidity, and CO2 levels must be regulated to ensure optimal bird health and productivity.

- Feeding and Watering Systems: Efficient systems to provide continuous access to feed and water are crucial.

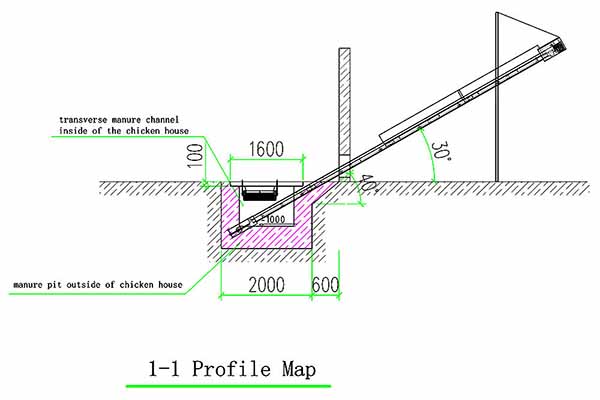

- Manure Management: Proper waste disposal and biosecurity measures are vital to prevent disease outbreaks.

- Equipment and Maintenance: Regular maintenance and replacement of equipment are necessary to ensure smooth operations.

Key Components of a 300,000 Chicken Commercial Poultry Cage System

| Component | Description |

|---|---|

| Cage Design | Sturdy and comfortable cages with dimensions suitable for the size of the birds. |

| Environmental Control | Climate control systems for temperature, humidity, and CO2 regulation. |

| Feeding System | Automated feeding systems to provide consistent feed rations. |

| Watering System | Continuous access to fresh water through automated drinking systems. |

| Manure Disposal | Efficient manure collection and disposal systems to maintain hygiene and biosecurity. |

| Monitoring Equipment | Systems to monitor bird health, productivity, and environmental conditions. |

Implementing a 300,000 chicken commercial poultry cage system requires careful planning and investment. The right equipment and design can significantly impact the success of the operation.

For instance, the Livi mechanical commercial poultry cage system offers a range of solutions tailored to the needs of Kenyan poultry farmers. Our systems are designed to maximize efficiency, reduce labor costs, and ensure the well-being of the chickens.

Benefits of Choosing Livi Mechanical Commercial Poultry Cage System

- Increased productivity due to efficient feeding and watering systems.

- Improved bird health and welfare through optimal environmental control.

- Reduced labor costs through automation.

- Long-term cost savings on maintenance and equipment replacement.

For a detailed analysis of your specific requirements and to rece ive a free design and equipment quotation, please contact us. Our team of experts is ready to assist you in achieving a successful poultry farming operation in Kenya.

ive a free design and equipment quotation, please contact us. Our team of experts is ready to assist you in achieving a successful poultry farming operation in Kenya.

Contact us today to start your journey towards a successful commercial poultry cage system for 300,000 chickens.