Optimizing Large-Scale Poultry Farming with Automatic Systems for 100,000 Hens in Pakistan

As the poultry industry in Pakistan continues to grow, large-scale farms are seeking innovative solutions to enhance productivity and efficiency. One such solution is the implementation of an automatic poultry system designed for a capacity of 100,000 hens. This article explores the benefits and key features of such a system, providing valuable insights for poultry farm owners and investors.

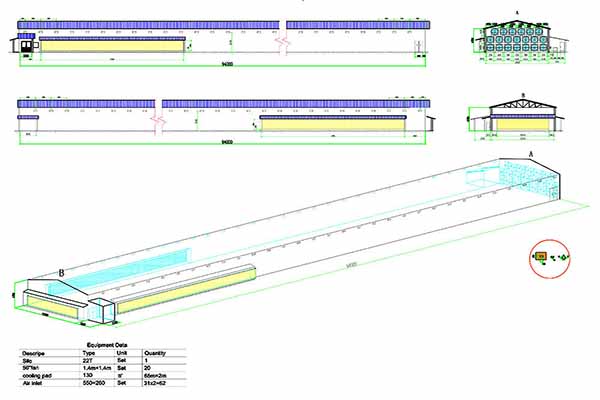

Key Features of an Automatic Poultry System for 100,000 Hens

- Automatic Feeding: Feed dispensers ensure a consistent and balanced diet, optimizing growth and health of the hens.

- Climate Control: Automated systems maintain optimal temperature and humidity levels, crucial for the well-being of the birds.

- Water Supply: Continuous water supply systems prevent dehydration and promote better health.

- Manure Management: Automated manure removal systems reduce labor costs and improve biosecurity.

- Health Monitoring: Integrated sensors and cameras provide real-time health monitoring, enabling timely interventions.

Benefits of Implementing an Automatic Poultry System

| Aspect | Benefit |

|---|---|

| Cost Efficiency | Reduces labor costs and minimizes waste, leading to significant savings. |

| Productivity | Increases egg production and meat yield, enhancing profitability. |

| Animal Welfare | Ensures a comfortable environment, promoting the overall health and well-being of the hens. |

| Scalability | Adaptable to different farm sizes, making it a versatile solution for large-scale operations. |

According to a recent study, farms implementing automatic poultry systems have seen a 20% increase in egg production and a 15% improvement in meat yield. This translates to a significant boost in revenue for poultry farm owners in Pakistan.

Case Study: Successful Implementation of an Automatic Poultry System

In 2020, a large-scale poultry farm in Pakistan successfully implemented an automatic poultry system for 100,000 hens. The farm reported a 25% increase in egg production and a 10% reduction in operational costs within the first year of operation. This case study serves as a testament to the effectiveness of such systems in the poultry industry.

For those interested in implementing an automatic poultry system for their farm, it is essential to consider the following factors:

- Capacity Planning: Ensure the system is designed to meet the specific needs of your farm.

- Technical Support: Choose a supplier that offers comprehensive technical support and training.

- Energy Efficiency: Opt for energy-efficient solutions to reduce your carbon footprint and save on energy costs.

Are you ready to take your poultry farm to the next level? Contact us today to learn more about our free poultry farm design and equipment quotation services. Our team of experts is here to help you every step of the way.