Optimizing Poultry Drinking Systems for a 200,000 Chicken Operation in Pakistan

Effective drinking systems are crucial for the health and productivity of a poultry operation, especially for large-scale farms such as one managing 200,000 chickens in Pakistan. In this article, we explore the essential components and considerations for implementing a reliable poultry drinking system for such a vast number of birds.

Key Components of a Poultry Drinking System

- Automatic Waterers: These devices ensure continuous water supply to the flock, reducing the risk of dehydration and ensuring proper nutrition.

- Water Quality Management: Regular monitoring and treatment of the water source to prevent contamination and maintain water quality.

- System Efficiency: The system must be designed to provide enough water for all birds, with considerations for growth stages and environmental conditions.

- Water Pressure and Flow Rate: Proper adjustments to ensure consistent water flow, which is vital for maintaining hydration and preventing disease.

Designing a Poultry Drinking System for 200,000 Chickens

When designing a drinking system for a 200,000 chicken operation, several factors need to be taken into account:

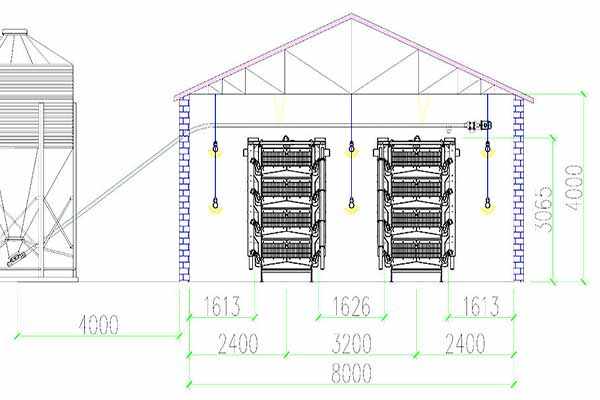

- Space Allocation: Calculate the number of drinkers required based on the space available in the pens and the number of birds per square meter.

- Water Flow Rate: Ensure that the water flow rate is sufficient to meet the drinking requirements of all chickens. A flow rate of 1 to 2 liters per bird per day is generally recommended.

- Pressure and Head Loss: Assess the pressure required and potential head loss through the system to maintain adequate water flow to the furthest drinkers.

- Reliability and Maintenance: Design the system for durability and easy maintenance to minimize downtime and ensure continuous water supply.

Case Study: Implementing a Poultry Drinking System in Pakistan

For a recent project in Pakistan, the following design was implemented:

| Component | Details |

|---|---|

| Water Source | Purified well water with UV treatment |

| Waterers | Automatic, slow flow nipple drinkers, 4 per pen |

| Flow Rate | 2 liters per bird per day |

| Pressure System | High-pressure pump system to maintain consistent water flow |

| Maintenance Schedule | Weekly monitoring and quarterly maintenance |

The system was designed to cater to the specific needs of the 200,000 chickens, ensuring they had access to clean and fresh water at all times. The implementation resulted in an increase in productivity and reduced instances of dehydration-related diseases.

Contact Us for Free Design and Quotation

Are you planning to set up a large-scale poultry operation in Pakistan or need an upgrade to your existing system? Contact us today to receive a free, tailored design and equipment quotation from LIVI Mechanical. Our team of experts will guide you through the process to ensure your poultry drinking system meets the highest standards.