Poultry Farming Cage Solution for 180,000 Chickens in Zambia

Understanding the Scale

Raising 180,000 chickens is no small feat, and it requires a well-thought-out poultry farming cage solution. In Zambia, where poultry farming is a crucial part of the agriculture sector, ensuring efficient and humane conditions for such a large flock is essential.

Data from the Zambia National Poultry Association shows that the country has over 2.5 million chickens. With such a high demand, investing in a scalable and effective cage solution is paramount.

Below are some key aspects to consider when implementing a cage solution for 180,000 chickens:

- Space Allocation: Ensure each chicken has ample space to move around. A general rule of thumb is around 0.6 square meters per chicken.

- Health Management: Regular monitoring and proper ventilation are crucial to prevent disease outbreaks.

- Feeding System: Implement an automated feeding system to ensure consistent nutrition for the chickens.

- Water Supply: A reliable water supply with regular checks to ensure cleanliness and access for all chickens.

Choosing the Right Cage Solution

The right cage solution for 180,000 chickens in Zambia should be designed to cater to the specific climate and operational needs of the farm. Here are some factors to consider:

- Material: High-quality, durable steel or aluminum is ideal for longevity and resistance to corrosion.

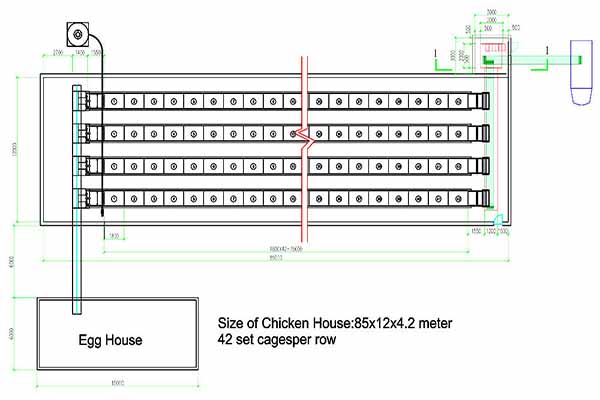

- Size and Layout: Modular designs that can be expanded or reconfigured as needed.

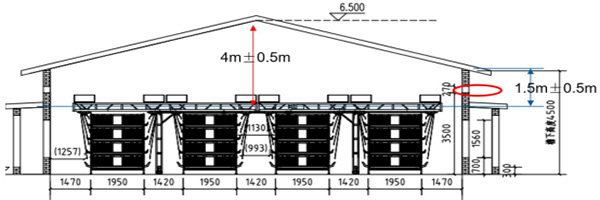

- Ventilation and Temperature Control: Adequate ventilation to maintain a healthy environment, with options for temperature control in extreme weather conditions.

- Accessibility: Easy to clean and maintain for hygiene purposes.

For a farm of this scale, it’s also important to consider the integration of technology. Smart systems that monitor health, productivity, and environmental conditions can greatly enhance farm efficiency.

Cost-Benefit Analysis

Investing in a quality poultry farming cage solution for 180,000 chickens can yield significant benefits in terms of productivity and disease prevention. Here’s a brief cost-benefit analysis:

| Cost Aspect | Benefit |

|---|---|

| Initial Investment | Long-term savings through increased productivity and reduced disease risk |

| Operational Costs | Reduced labor costs due to automated systems and improved efficiency |

| Maintenance and Upkeep | Longevity of the system through quality materials and design |

Conclusion

For any poultry farmer or investor in Zambia looking to manage 180,000 chickens, a well-designed cage solution is the cornerstone of a successful operation. By considering the factors outlined above, you can make an informed decision that will ensure the health and welfare of your flock, as well as maximize your investment returns.

investment returns.

Are you ready to take the next step in enhancing your poultry farming operation? Contact LIVI Mechanical today to get a free chicken farming design plan and equipment quotation. Our team of experts is here to help you every step of the way.