Poultry Ventilation System for 400,000 Chickens in Kenya: A Comprehensive Guide

Effective ventilation is crucial in poultry farming to ensure the health and productivity of the flock. For a 400,000 chicken operation in Kenya, a well-designed ventilation system is essential to maintain optimal conditions. This article explores the key aspects of a poultry ventilation system tailored for such a large-scale operation.

Understanding the Ventilation Needs

A poultry ventilation system must address the following factors to support a 400,000 chicken flock:

- Airflow Rate: A minimum of 20 cubic meters per minute per bird is recommended to ensure adequate oxygen supply and control humidity.

- Air Quality: High-efficiency particulate air (HEPA) filters can be used to reduce dust and ammonia levels, improving air quality.

- Temperature Control: The system should maintain a consistent temperature range, typically between 18-23°C, to optimize growth rates and reduce disease risk.

- Energy Efficiency: Opt for energy-efficient fans and controls to reduce operational costs.

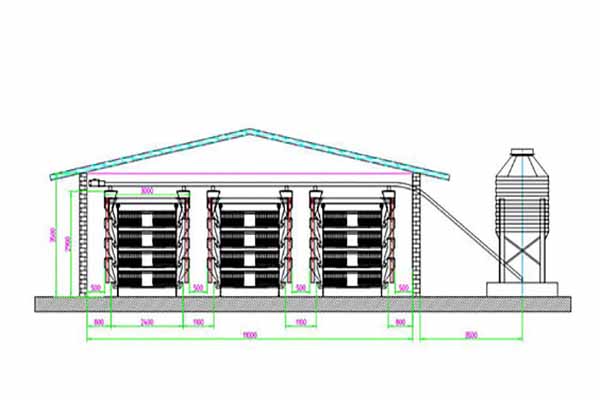

Designing the System

The design of a ventilation system for 400,000 chickens involves several components:

- Intake and Exhaust Fans: Install intake fans at the bottom of the building and exhaust fans at the top to create a pressure difference that drives air flow.

- Control Panels: Use automated control panels to manage fan speeds and airflow based on temperature and humidity sensors.

- Heating and Cooling Systems: Include heating and cooling units to maintain the desired temperature range.

- Humidity Control: Employ humidifiers and dehumidifiers to manage humidity levels.

Case Study: Kenya’s Largest Poultry Farm

Kenya’s largest poultry farm, with a capacity of 400,000 chickens, implemented a ventilation system with the following specifications:

| Component | Specification |

|---|---|

| Intake Fans | 10 fans, 50,000 CFM each |

| Exhaust Fans | 10 fans, 50,000 CFM each |

| Control Panels | Advanced automated control system |

| Heating Units | 5 units, 200 kW each |

| Humidifiers/Dehumidifiers | 2 units each |

This system has been instrumental in maintaining a healthy environment for the chickens, resulting in reduced disease incidence and improved growth rates.

Conclusion

Implementing a poultry ventilation system for a 400,000 chicken operation in Kenya requires caref ul planning and attention to detail. By focusing on airflow rate, air quality, temperature control, and energy efficiency, farmers can create an optimal environment for their flock. For a customized ventilation solution and equipment quotes, contact us today for a free poultry farm design and quotation.

ul planning and attention to detail. By focusing on airflow rate, air quality, temperature control, and energy efficiency, farmers can create an optimal environment for their flock. For a customized ventilation solution and equipment quotes, contact us today for a free poultry farm design and quotation.