Revolutionizing Poultry Farming: The Automatic Chicken Cage System for 260,000 Chickens in Kenya

The poultry industry in Kenya is experiencing significant growth, and with it comes the need for efficient and automated solutions to manage large-scale chicken farming operations. One such innovation is the Automatic Chicken Cage System designed to accommodate up to 260,000 chickens. In this article, we will explore the benefits of this system, its impact on productivity, and why it’s a game-changer for poultry farmers in Kenya.

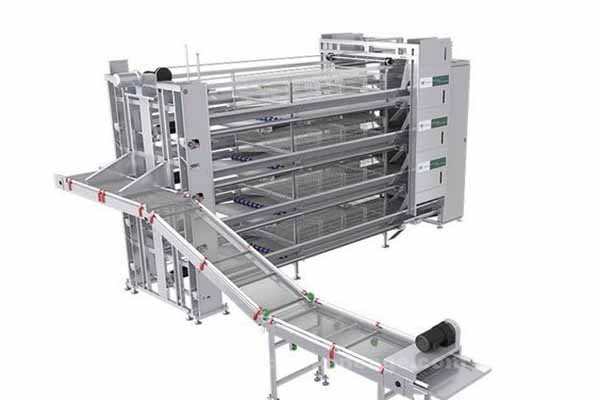

Introduction to the Automatic Chicken Cage System

The Automatic Chicken Cage System is a cutting-edge solution that integrates automation into the chicken farming process. This system is designed to maximize efficiency, reduce labor costs, and ensure the health and well-being of the chickens. Here’s a breakdown of its key features:

– Capacity: The system is designed to house up to 260,000 chickens, making it suitable for large-scale farms.

– Automation: The system is fully automated, reducing the need for manual labor and increasing productivity.

– Health Monitoring: Integrated sensors monitor the chickens’ health, ensuring early detection of any issues.

– Climate Control: The system maintains optimal temperature and humidity levels, creating a comfortable environment for the chickens.

Benefits of the Automatic Chicken Cage System

1. Increased Productivity: With the automated system, farmers can manage a larger flock of chickens, significantly increasing their productivity.

2. Reduced Labor Costs: The system minimizes the need for labor, as most processes are automated.

3. Enhanced Chicken Health: Regular monitoring and controlled environment ensure that the chickens remain healthy, leading to higher survival rates.

4. Cost-Effective: Despite the initial investment, the long-term savings on labor, feed, and health care make the system cost-effective.

Case Study: Success Stories

– Farm A: This farm has seen a 30% increase in productivity since implementing the Automatic Chicken Cage System.

– Farm B: The farm’s mortality rate decreased by 20% due to the controlled environment and early health monitoring.

– Farm C: The system’s energy efficiency has led to a 15% reduction in electricity costs.

How the System Works

– Feeding: Automated feeders dispense feed at regular intervals, ensuring that the chickens receive the right amount of nutrition.

– Watering: Watering systems maintain clean water supply for the chickens.

– Ventilation: Automated ventilation systems control air circulation, ensuring a comfortable environment.

– Cleaning: The system includes automated cleaning cycles to maintain hygiene.

Conclusion

The Automatic Chicken Cage System for 260,000 chickens in Kenya is a testament to the technological advancements in the poultry industry. It offers numerous benefits, from increased productivity to reduced costs. As the industry continues to grow, such innovative solutions are crucial for farmers and investors looking to stay competitive.

If you’re considering investing in an Automatic Chicken Cage System for your farm, contact us today for a free, detailed design and equipment quote. Our team of experts is ready to assist you in maximizing the potential of your poultry operation.